Which shipping method aligns best with your business needs: FCL or LCL?

The freight forwarding market in the Philippines is experiencing significant growth. By 2025, the volume of goods transported is projected to reach 322.48 billion ton-kilometers (TKM), reflecting the country’s expanding role in global trade.

FCL offers dedicated space and faster timelines for bulk shipments, while LCL provides flexibility and cost efficiency for smaller loads.

TL;DR:

- FCL is best for bulk shipments. You get exclusive container use, faster transit, fewer touchpoints, and lower per-unit costs at scale.

- LCL suits smaller loads. You share space, pay only for what you use, and avoid overcommitting on inventory.

- FCL = Speed, control, and cost-efficiency for high-volume or time-sensitive shipments.

- LCL = Flexibility and lower upfront costs for testing products or managing lean supply chains.

- Use FCL when you’re shipping in bulk or on tight timelines.

- Use LCL when volumes are low, irregular, or cash flow is a concern.

What is FCL?

Full Container Load (FCL) shipping refers to a method where your goods occupy an entire container, typically 20 feet or 40 feet in length, regardless of whether it’s filled. This mode is commonly used for larger shipments that benefit from dedicated space, more control, and faster transit times.

If you’re importing products in bulk or dealing with high-demand SKUs, FCL gives you a streamlined shipping process with fewer touchpoints. You avoid the delays and risks that can come from sharing space with other shippers, making it a strong choice for businesses looking to maintain consistency and scale efficiently.

As the Philippines improves its shipping infrastructure, indicated by a rise in the Liner Shipping Connectivity Index (LSCI), a measure of a country’s integration into global shipping networks, from 100 in Q1 2023 to 179.51 by Q2 2024, FCL shipping becomes more viable for businesses.

Next up, let’s take a closer look at when opting for FCL makes the most sense for your business.

When to Choose FCL?

FCL is ideal when shipment volume is high enough to justify the cost of the entire container. But it’s not only about spaceit’s also about speed, reduced risk, and simplified logistics.

Here’s when choosing FCL makes practical sense:

- You’re shipping a high volume: If your goods take up most or all of a container, FCL usually becomes more cost-effective per unit.

- You want minimal cargo handling: FCL cargo is sealed at origin and opened only upon arrival, reducing chances of damage or loss.

- Speed is critical to your operations: With no need for consolidation or deconsolidation, FCL shipments generally move faster.

- You’re moving high-value, branded, or fragile goods: Exclusive container use means your cargo is better protected during transit.

- You need reliable scheduling: FCL simplifies coordination, especially for time-sensitive deliveries or repeat import cycles.

For retailers preparing for peak seasons or businesses replenishing large volumes of stock, FCL ensures better timeline control and fewer logistical variables. Now that we know when FCL is the right choice, let’s dive into the specific features that make it an attractive option for larger shipments.

Also read: Understanding ASN: Advanced Shipping Notice Explained

Features of FCL Shipping

FCL offers a set of advantages that make it highly effective for businesses moving goods across borders on a large scale. These features enable more efficient planning, greater control over logistics, and long-term cost savings.

- Exclusive container usage: With FCL, you’re not sharing space with other shipments. This gives you complete control over how your goods are packed, labeled, and arranged—ideal for product lines that require specific stacking, handling, or separation protocols.

- Quicker port turnaround: FCL containers don’t require bundling with other cargo or sorting at the destination. This reduces time spent at ports and warehousing hubs, allowing for faster last-mile delivery and better coordination with downstream operations.

- Lower risk of damage: Since your shipment is sealed at its origin and remains unopened until it reaches its final destination, there are fewer handling stages. This minimizes the chance of breakage, loss, or contamination, which is especially critical for delicate, branded, or high-value goods.

- Simplified customs process: A single set of documentation applies to the entire container, making customs clearance more straightforward and less time-consuming. It also reduces the risk of discrepancies that can arise when managing multiple consignees in one container.

- Scalable cost efficiency: Although the upfront cost of FCL may appear higher than that of shared-container options, it becomes more economical as your volume increases. When fully utilized, the per-unit freight cost often decreases significantly, making it a more cost-effective long-term solution for businesses that are growing.

Build a scalable import model with dedicated FCL shipments through Inspire Solutions

Book a consultation todayFCL is best suited for businesses that prioritize control, consistency, and the ability to meet demand without disruption, especially when managing recurring imports or preparing for sales-driven spikes in orders. With that in mind, let’s now move on to understanding how LCL shipping compares in terms of flexibility and cost-effectiveness.

What is LCL?

Less than Container Load (LCL) shipping refers to a method where your goods share a container space with cargo from other businesses. It’s designed for smaller shipments that don’t require a full container, making it a cost-efficient way to import or export without overcommitting on volume.

LCL shipping is beneficial for e-commerce startups, SMEs, and growing retailers who are still testing new products or markets. You only pay for the space you use, which helps reduce upfront investment while maintaining access to global suppliers and inventory sources.

Before we look into the specifics of when LCL might be your best option, let’s first take a look at some scenarios where it could shine.

When to Choose LCL?

LCL is the practical choice when your shipment isn’t large enough to fill a full container. It’s often used during early-stage product launches, seasonal restocks, or when you’re importing limited batches to test new items.

You’ll benefit from LCL shipping when:

- Your cargo volume is low or irregular: If you’re shipping small quantities or have inconsistent order sizes, LCL avoids the need to wait until a full container is filled.

- You’re testing a product line: When launching a new product, LCL allows you to bring in limited stock without committing to bulk orders.

- You want to manage cash flow: Smaller shipments mean smaller freight bills, which helps businesses maintain financial flexibility.

- You need access to global suppliers: LCL opens the door to global sourcing, even for businesses not yet operating at scale.

- You’re operating across different markets: For sellers distributing inventory across multiple regions, LCL can help split shipments more efficiently.

This option works well when delivery timelines are flexible and cost control is more important than speed or exclusivity. Now, let’s examine the key advantages of LCL and how it supports businesses with smaller shipment sizes and flexible needs.

Also read: How to Safely Pack and Ship Fragile Items

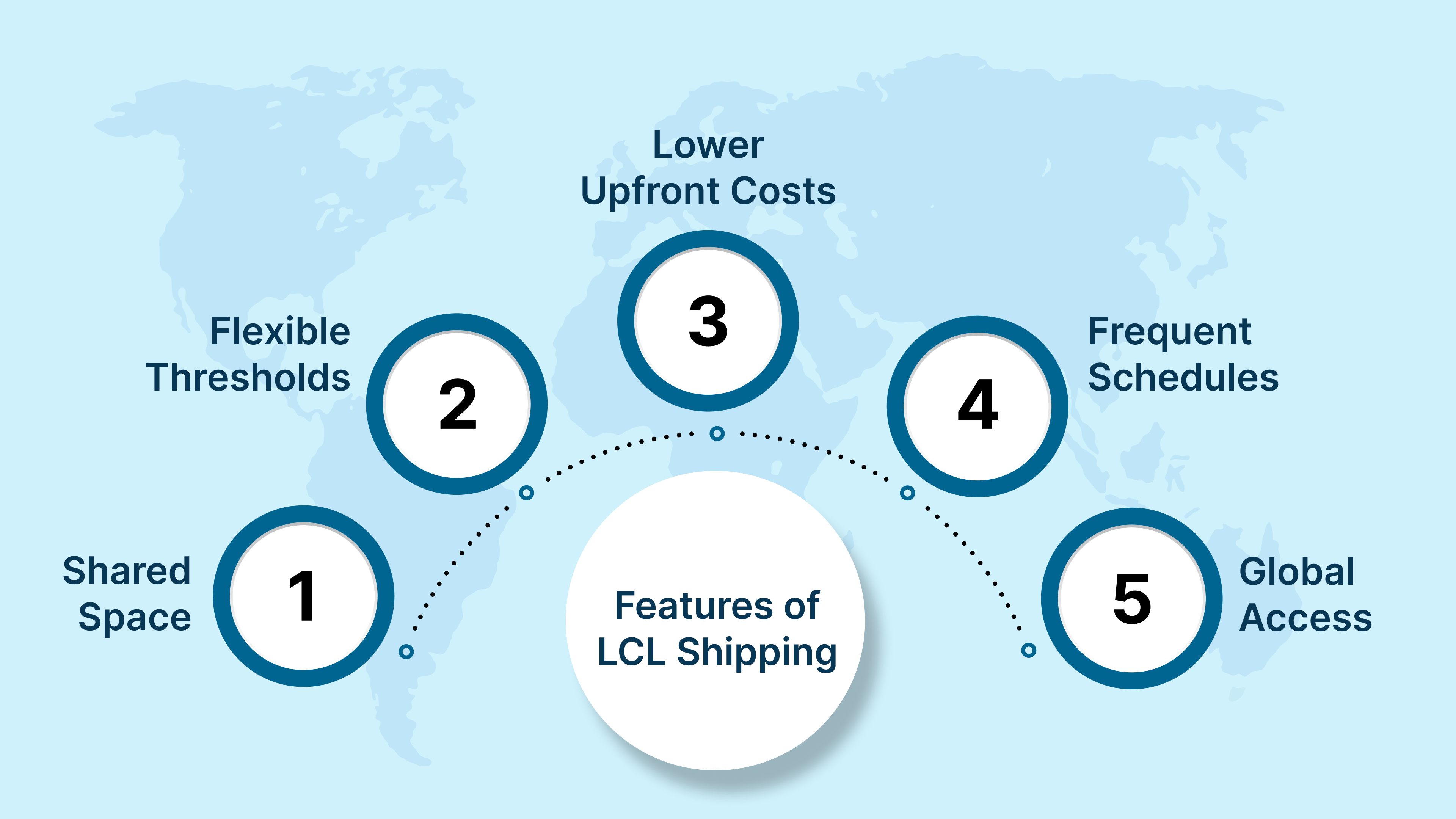

Features of LCL Shipping

LCL shipping offers unique advantages tailored to small to medium-sized businesses, startups, and growing sellers who may not yet have the volume to justify full-container bookings. While it introduces more coordination, the flexibility it offers makes it a viable option for agile, cost-conscious operations.

- Shared container space: Your cargo shares a container with goods from other businesses, allowing you to move products internationally without waiting to accumulate enough volume for a full load. This setup reduces cost barriers to entry and ensures you’re not paying for unused space, which is ideal when working with limited stock or during early-stage product testing.

- Flexible volume thresholds: Whether you’re shipping five cartons or half a container’s worth, LCL adapts to your needs. This flexibility supports businesses with fluctuating demand, varied product SKUs, or limited warehouse storage, making it easier to align shipment size with current sales forecasts.

- Lower upfront logistics costs: Because you only pay for the space your cargo occupies (measured by cubic meters or weight, whichever is higher), LCL reduces initial freight expenses. This is particularly helpful for managing inventory turnover and cash flow, especially when launching new products or entering new markets without heavy upfront investment.

- Frequent consolidation schedules: Many freight providers offer regular weekly or biweekly LCL departures from key ports. That means you don’t have to wait long to ship, even if your volume is small. This enables better inventory planning and reduces delays in getting products into customers’ hands.

- Global access for small businesses: LCL allows even the smallest sellers to participate in international trade. You gain access to trusted overseas suppliers and manufacturers without needing to maintain high inventory levels or lease extensive warehouse space. It also provides you with the agility to respond to changing consumer demand through faster product testing cycles.

While LCL shipments may involve additional touchpoints, such as deconsolidation at destination ports and extra documentation, these trade-offs are often worthwhile for businesses looking to minimize cost and operational risk during their growth phase.

Having explored the main features of both FCL and LCL, let’s now compare these two options head-to-head to help clarify which one is right for you.

FCL vs LCL Shipping: Key Differences

Choosing between FCL (Full Container Load) and LCL (Less Than Container Load) shipping depends on several factors. Understanding these differences will help you align your shipping strategy with your business goals, whether you’re managing regular bulk imports or shipping test batches into a new market.

The table below outlines the most critical differences between FCL and LCL to help you decide which suits your operational needs best:

| Factor | FCL (Full Container Load) | LCL (Less than Container Load) |

|---|---|---|

| Container Usage | Exclusive use of the entire container. | Shared container space with other shippers. |

| Cost Structure | Flat rate for the full container, more cost-efficient for large shipments. | Charged based on volume (CBM) or weight; lower upfront cost for small loads. |

| Minimum Volume Needed | Recommended for high-volume shipments that can nearly fill the container. | No minimum; suitable for small or irregular volumes. |

| Transit Time | Generally faster—no delays from consolidation or deconsolidation. | Slightly slower due to additional handling at both origin and destination. |

| Handling & Risk | Less handling, lower risk of damage or loss. | More touchpoints increase the risk of handling and potential damage. |

| Customs Clearance | Easier with one shipper’s documentation. | Involves multiple consignees; documentation and clearance can be complex. |

| Scheduling Flexibility | Requires planning based on available volume. | More frequent departures are suitable for agile shipping needs. |

| Inventory Strategy | Ideal for bulk inventory and consistent replenishment cycles. | Works well for test shipments, new products, or limited stock needs. |

| Cost per Unit | Lower when the container is full or near capacity. | Higher per unit, but manageable at small scales. |

This comparison helps clarify that FCL is optimal when you’re prioritizing speed, volume, and security, while LCL is ideal for flexibility, affordability, and smaller shipment sizes.

Unsure between FCL or LCL? Inspire Solutions aligns your shipping strategy with your business goals

Get a Quote NowNext, let’s take a look at some real-world examples to illustrate how FCL and LCL work in various business situations.

Also read: Essential Shipping Documents for Import and Export

Examples and Practical Applications

Understanding the theory behind FCL and LCL is helpful, but seeing how each method plays out in practice can make your decision more confident. Whether you’re an online retailer entering the Philippine market or a growing brand managing cross-border shipments, the correct shipping method should match your inventory scale, speed requirements, and budget constraints.

Here are practical scenarios where FCL or LCL would be the better fit:

- Example 1: Bulk Inventory for Monthly Online Sales

You’re an established e-commerce seller importing skincare products from South Korea. Your monthly sales volume justifies moving 20–25 CBM of inventory consistently.

- Best fit: FCL

- Why: Since you’re nearing full-container capacity, FCL provides a better rate per unit, reduces customs delays, and protects your branded packaging from unnecessary handling.

- Example 2: Product Launch for a Niche Market

You’re a startup launching a niche line of eco-friendly tumblers and want to test market response in the Philippines with just 2 CBM of stock.

- Best fit: LCL

- Why: You don’t need a full container. LCL allows you to import products into the country without overinvesting in shipping or inventory, making it perfect for early-stage demand validation.

- Example 3: Seasonal Restocking with Tight Timelines

A home décor SME is preparing for a holiday sale campaign and needs inventory delivered quickly from Vietnam to Metro Manila.

- Best fit: FCL

- Why: Transit speed is critical, and FCL avoids the delays of deconsolidation. Additionally, the full container ensures that goods arrive securely and on time during the high-demand season.

- Example 4: Multi-SKU Sampling from Different Suppliers

A fashion retailer is testing new accessories from multiple suppliers in China. The total volume is under 5 CBM and includes a variety of SKUs, such as bags, scarves, and belts.

- Best fit: LCL

- Why: LCL enables you to consolidate shipments from multiple suppliers into one container without paying for unused space. It supports a wide variety of SKUs, thereby lowering investment risk.

These examples show that the proper shipping method is not just about volume; it’s about aligning shipping choices with your business goals, timeline, and cost strategy.

With this in mind, it’s time to consider how to make your next shipment even more seamless with the right logistics partner like Inspire Solutions Asia.

Ready to Ship Smarter? Simplify Logistics with the Right Partner

Choosing between FCL and LCL shipping goes beyond pricing—it depends on your volume, lead times, and delivery goals. Whether you’re managing bulk imports or testing new products, the right choice affects your speed, cost-efficiency, and overall fulfillment flow. Striking this balance is essential for scaling sustainably and meeting rising customer expectations in today’s digital marketplace.

At Inspire Solutions Asia, we help you simplify logistics at every stage. Our sourcing services connect you with trusted international suppliers, while our tech-enabled fulfillment solutions improve accuracy and nationwide delivery performance. With real-time inventory visibility and optimized warehousing, we ensure your operations stay agile and efficient. Our Same-Day and Next-Day Delivery options keep your customers satisfied, and our flexible financing solutions support your growth without straining cash flow.

Take control of your supply chain today.

Book a consultation with us.FAQ

- How to differentiate FCL and LCL?FCL uses an entire container for one shipment, while LCL shares space with other shipments, making it more suitable for smaller loads.

- What is the difference between FCL and LCL cost?FCL is more cost-effective for larger shipments, while LCL is cheaper upfront for smaller shipments but has higher per-unit costs due to extra handling.

- Is FCL the same as LCL?No, FCL is for shipments that fill an entire container, while LCL is for smaller shipments that share container space with other goods, which means FCL offers exclusivity and faster shipping.

- What is 40 FCL mean?40 FCL refers to a 40-foot container used in Full Container Load shipping. It provides more space than a 20-foot container and is commonly used for larger shipments.

- How much is 1 FCL in kg?A 40-foot FCL container can carry up to 27,000 kg, but the exact weight capacity depends on the type of goods being shipped.