The Philippine retail and logistics market is undergoing rapid evolution. The Philippine Statistics Authority (PSA) reported a 9.4% increase in external trade in goods for January 2025 and a 10.7% rise in February 2024, signaling heightened logistics and inventory movement needs. Moreover, the PSA’s 2023 List of Establishments recorded over 1.24 million business enterprises, with a significant portion being micro, small, and medium enterprises (MSMEs), which heavily depend on effective warehousing and inventory management for smooth operations.

With such growth and demand for more efficient inventory practices, businesses must find ways to optimize their inventory strategies to avoid excess stock or stockouts, which can harm cash flow and customer satisfaction. This blog explores essential inventory optimization techniques, including Just-in-Time inventory, ABC Analysis, and automated replenishment systems, designed to help businesses navigate the complexities of the modern supply chain and enhance operational efficiency.

Inventory optimization involves maintaining optimal stock levels that are sufficient to meet customer demand without tying up cash in excess products. You’re aiming for stability: avoid delays, meet order expectations, and keep your capital available for high-impact areas, such as marketing, fulfillment, or product expansion.

By applying innovative inventory optimization strategies, you can eliminate unnecessary storage costs, manage the risk of stockouts, and foster long-term business growth. Whether you’re managing a single warehouse or scaling across multiple channels, gaining control over your inventory enables you to operate more efficiently and respond more quickly to customer needs.

If you’re looking to simplify your supply chain while protecting your bottom line, getting your inventory strategy right is a smart place to start. So, how do you build a system like that? It begins with choosing the right mix of techniques.

Managing inventory involves more than just maintaining stock levels; it is essential for controlling costs, optimizing capital, and ensuring prompt demand fulfillment. By implementing effective inventory optimization strategies, businesses can strike a balance between efficiency and customer satisfaction, making informed purchasing decisions. Below are seven proven strategies that enable companies to operate efficiently and respond effectively.

Just-in-Time Inventory allows you to stock items only as needed, timing replenishment to arrive just before orders are shipped. This strategy reduces storage and handling costs, prevents aging stock, and improves liquidity. It’s effective with consistent demand and reliable suppliers. A study of food manufacturers in Davao del Sur found a mean satisfaction score of 3.94 out of 5 for Just-in-Time (JIT) from inventory managers, indicating its effectiveness in reducing costs and enhancing efficiency.

For instance, if your monthly volume is 1,000 units and each unit costs PHP 200, holding three months’ worth of stock would tie up PHP 600,000. Switching to a one-month supply reduces the cost to PHP 200,000, leaving you with PHP 400,000 in cash that can be used elsewhere in the business.

ABC Analysis sorts your products into three categories based on value and turnover. Category A includes high-value items that sell in smaller volumes. Category B covers moderately priced goods with average demand. Category C includes low-cost items sold in high volume.

This method lets you focus attention where it matters most. You’ll spend more time managing A items, where stockouts or overstocking are expensive, and automate or schedule B and C items on simpler reorder cycles.

Here’s a simple breakdown:

| Category | % of Inventory | % of Inventory Value |

|---|---|---|

| A | 10% | 70% |

| B | 20% | 20% |

| C | 70% | 10% |

This clear separation enables you to apply different management styles to various items and utilize your working capital effectively.

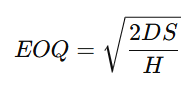

EOQ is a formula that calculates the optimal quantity to order, aiming to minimize total ordering and holding costs. If you often wonder whether you’re buying too much or too little, this strategy brings clarity through math.

The EOQ formula is:

Where:

Consider the following example: Your yearly demand is 5,000 units, the ordering cost is PHP 500, and the holding cost per unit is PHP 20.

Therefore, ordering 500 units at a time would result in the lowest combined ordering and storage costs.

This strategy involves holding a buffer of extra stock to protect against unexpected delays or spikes in demand. While it may seem like an additional cost on paper, safety stock protects your reputation and revenue when things don’t go as planned.

Suppose your average daily demand is 100 units and your supplier’s lead time is 7 days. Maintaining a safety stock of 700 units provides coverage for one complete delay cycle. This cushion becomes especially important during seasonal peaks or supplier disruptions, helping to avoid cancelled orders or delayed shipments.

Predicting future sales based on past data enables you to match your inventory to actual market behavior. By studying sales trends, seasonal patterns, and promotional cycles, you can prepare ahead rather than react late.

For products with irregular sales or seasonal fluctuations, this method ensures your warehouse is in sync with actual demand. A simple way to get started is by applying a 3-month moving average to your sales history, which smooths out short-term fluctuations and provides a clearer picture of likely demand.

With Vendor-Managed Inventory, you allow your supplier to monitor your stock levels and replenish them based on real-time needs. It works best when you have stable purchasing cycles and long-term supplier relationships.

VMI reduces the time and effort spent on forecasting and reordering. Suppliers restock based on agreed thresholds, making the process more consistent and often faster. This improves product availability and minimizes over-ordering. The key is having shared visibility; when your vendors see what’s moving, they can supply accordingly without waiting for you to raise a purchase order.

This method utilizes software that tracks your inventory in real-time and triggers reorder points based on live data. Once a product’s price drops below a set threshold, a new order is automatically generated.

Automated systems are advantageous when your sales channels scale or when you manage multiple locations. They eliminate the guesswork and reduce errors from manual tracking. Systems like NetSuite and TradeGecko can link with your POS or sales platform to keep stock aligned with order flow. This lets you maintain fast fulfillment without micromanaging stock levels.

Mastering these inventory optimization strategies gives you more than control, and it brings stability to your operations, reliability for your customers, and agility to your decision-making.

You’ve now seen the main techniques. Next, we’ll discuss how to tailor these methods to create a strategy that aligns with your specific goals and operations.

Read: How to Track Inventory: Steps and Tips

After selecting the right inventory optimization strategies for your business, the next phase is to build a system that integrates these methods into a cohesive and efficient operation. Strategy development focuses on aligning data, tools, and processes to support better decisions and faster response times.

To create a well-integrated inventory strategy, consider the following steps:

Utilize a centralized system to consolidate data on inventory, sales, procurement, and logistics. This allows for:

Move beyond high-level projections by:

Distribute stock based on demand geography to cut down lead times and reduce waste:

These steps support a more innovative, leaner inventory system that aligns with real-world conditions. You’re not just managing stock, you’re actively improving how it flows across your supply chain.

Next, let’s examine how these strategies perform when supported by the right technology tools.

As your business grows, manual inventory management quickly becomes a roadblock. Tracking stock across multiple platforms, sales channels, and warehouses demands more precision than spreadsheets can offer. That’s where smart technology steps in to support inventory optimization strategies that actually scale with your goals.

Managing fluctuating demand, delayed shipments, and changing customer behavior makes stock predictions unsustainable. AI and machine learning analyze historical sales data, seasonal trends, and pricing variations to provide more accurate demand forecasting. The global AI in logistics market is valued at $26.35 billion in 2025, projected to reach $707.75 billion by 2034, with a compound annual growth rate (CAGR) of 44.4%. Here’s what that means for you:

These systems don’t replace your strategy; they sharpen it. You’re not just reacting to trends anymore; you’re working ahead of them with better data.

Managing orders across multiple platforms, such as Shopify, Amazon, Lazada, and your warehouse, is simplified with the right inventory management software. Solutions like NetSuite, SAP, and TradeGecko provide built-in forecasting, automate reorder points, enable multi-channel syncing, and offer custom reporting.

With these platforms, you can:

This automation eliminates manual errors and provides a clear picture of what’s available, what’s in motion, and what’s holding you back.

To effectively manage inventory, visibility is crucial. Utilizing RFID tags and IoT sensors enables you to track inventory movement throughout your supply chain with precision, down to the level of each item or pallet. This technology provides comprehensive insights into inventory dynamics, enabling more informed decision-making and enhanced operational efficiency. Here’s what this entails:

This real-time insight enables you to respond more quickly when demand shifts, ensuring your inventory is aligned with your order volume without overcompensation.

Inspire Solutions Asia integrates RFID-based inventory visibility into our warehousing operations, giving you complete transparency from inbound shipment to customer delivery.

Innovative tools not only streamline processes but also enable quicker decision-making and more efficient inventory optimization strategies. Additionally, collaborating closely with your suppliers can significantly improve stock accuracy and enhance product availability.

Once your tech is in place, it’s time to track results. We’ll now cover the key performance indicators (KPIs) that show whether your inventory approach is working.

Read: Comprehensive Guide to Finished Goods Inventory Management

Tracking the right inventory performance indicators helps you know whether your inventory optimization strategies are working. These metrics point directly to what matters most: healthy cash flow, faster fulfilment, fewer stockouts, and smarter resource use. Here’s how each KPI brings you closer to operational control and more reliable business outcomes:

This indicates how quickly inventory is being sold and replenished over a specific period. A higher turnover means you’re not tying up cash in unsold goods, and your inventory aligns with what your customers buy. Use this formula to calculate it:

Inventory Turnover = Cost of Goods Sold / Average Inventory

For example, if your cost of goods sold for the quarter is PHP 1,800,000 and your average inventory is PHP 300,000, your turnover rate is 6. That’s a good indicator that you’re stocking well and selling fast. When you apply accurate inventory optimisation strategies, this number will show consistent improvement, reflecting efficient buying patterns and fewer excess items sitting idle.

A stockout occurs when an item is unavailable to a customer, resulting in lost revenue and damaged trust. The stockout rate reflects the frequency at which this happens. For instance, if you had 1,200 orders last month and 30 were unfulfilled due to stock issues, your stockout rate is 2.5%. Aim to minimize this number. Improved demand forecasting, buffer stock, and smarter reorder points can reduce disruptions and boost customer satisfaction.

This is the percentage of customer orders fulfilled entirely from available stock. A high fill rate means you’re stocking the right items in the right quantities. For instance, a 97% fill rate means only 3 out of every 100 orders are delayed or only partially fulfilled. That consistency builds customer confidence. It also demonstrates that your inventory optimization strategies are closely aligned with actual demand, avoiding both overbuying and stockouts. Fill rate is beneficial if you’re handling multiple sales channels or tight delivery timelines.

These are the ongoing expenses associated with holding unsold inventory, including warehousing, insurance, depreciation, and even shrinkage. Let’s say your monthly carrying costs are PHP 85,000, but half of that is going toward items that haven’t moved in three months. That’s cash stuck in the system. Lowering carrying costs means your capital is working for you, not sitting in storage. With smarter buying cycles, leaner inventory levels, and Inspire Solutions Asia’s real-time stock visibility, these costs can be reduced without compromising service quality.

This measures the time from placing an order with your supplier to receiving the goods for sale. A long cycle time can hinder responsiveness to demand changes, promotions, or urgent orders. For instance, cutting the order cycle from 25 days to 15 enables quicker inventory turns and reduces the need for large, upfront purchases. Shortening this cycle enhances cash flow and flexibility, allowing for faster responses without over-inflating inventory levels. Our same-day and next-day fulfillment support shorter cycles without adding pressure on your team.

Now that you know what to measure, it’s time to put the strategies into motion, with help from Inspire Solutions.

Inventory optimization strategies become far more effective when paired with the right operational tools. Inspire Solutions provides end-to-end support that simplifies your inventory flow—from sourcing to last-mile delivery- so you can stay agile, reduce overhead, and serve customers faster. Here’s how we help make it happen:

Whether you’re a new seller testing the waters or an established retailer looking to scale, Inspire Solutions helps you put your inventory strategies into action, without the usual guesswork.

Inventory optimization strategies are crucial for e-commerce businesses of all sizes, especially in dynamic markets like the Philippines. Whether you are a startup mitigating the risk of overstocking, an SME handling seasonal demand, or an international seller venturing into new territories, optimizing your inventory can enhance cash flow, improve operational efficiency, and increase customer satisfaction.

At Inspire Solutions, we help businesses like yours bring those strategies to life. From real-time inventory tracking and flexible warehousing to sourcing, importation, financing, and rapid delivery services, we provide everything you need to scale efficiently in today’s digital marketplace, without the operational hassle.

Ready to streamline your operations and take control of your inventory? Contact us today and see how Inspire Solutions can support your next stage of growth.