Are high logistics costs eating into your profit margins?

In the Philippines, customs clearance alone can account for 35% to 60% of total logistics expenses, making it the most significant contributor to product costs. Maritime transportation also plays an important role, with freight rates and surcharges accounting for 20% to 40% of overall logistics costs. On average, an imported container costs approximately $5,300 ( PHP 295,035), which is roughly 10% of the stock value. Inland logistics, including trucking and warehousing, further add 10% to 25% to expenses. Together, these figures highlight the need for businesses to streamline logistics processes.

This blog will explore how reducing logistics costs can boost efficiency and profitability while offering practical strategies and insights on cutting expenses in your supply chain.

Logistics costs refer to the expenses incurred for managing and transporting goods within a supply chain. These include procurement, warehousing, transportation, inventory management, and fulfillment. The logistics costs incurred by businesses can vary based on the complexity of their supply chain and operational models. Generally, logistics costs include:

The key to managing and reducing logistics costs lies in understanding these components and focusing on where improvements can be made. Next, let’s take a closer look at the factors that affect these costs, so you can better understand what impacts your bottom line.

Logistics costs are influenced by a variety of internal and external factors that can significantly impact a business’s overall expenses. Understanding these factors is crucial for effectively managing and minimizing logistics costs. The primary factors include:

Transportation significantly contributes to logistics expenses, with fuel prices being a key factor in these costs. Fluctuations in fuel prices directly impact transportation costs, particularly for businesses that rely on long-distance shipping. This variability complicates cost forecasting and planning; therefore, companies need to monitor fuel trends and develop cost-effective transportation strategies closely. In the Philippines, where the freight transport segment commands about 67% of the logistics market, and given the country’s reliance on imported fuel and high fuel prices, the impact of fuel price fluctuations is substantial

Labor availability and cost significantly affect logistics expenses. Wages for warehouse staff, drivers, and managers contribute to overall labor costs. A shortage of skilled workers can lead to increased expenses as businesses compete for talent. Additionally, labor inefficiencies and high turnover can further raise operational costs, impacting the supply chain.

The distance between warehouses, fulfillment centers, and customers has a significant impact on transportation costs. Longer distances result in higher fuel consumption, extended delivery times, and increased expenses. In areas with high transportation costs, such as tolls or expensive warehouse rentals, logistics expenses can increase.

Supply chains face seasonal demand fluctuations that affect logistics. Peak periods, like holidays, lead to increased shipping volumes and higher costs for carriers, warehousing, and labor. To avoid overspending, businesses need to plan accordingly. For instance, during the holiday season, major ports like Manila South Harbor and Manila International Container Terminal saw peak yard utilization, with MICT hitting 87.47% in January 2025 due to the surge.

International trade regulations, tariffs, and customs clearance can raise logistics costs. Changes in these policies can impact the time and expenses associated with importing and exporting goods. Companies engaged in cross-border trade must stay up-to-date on regulations and account for costs such as duties and taxes.

Technology in logistics affects costs. Investments in transportation management systems (TMS), warehouse management systems (WMS), and real-time tracking tools enhance efficiency but incur upfront costs. Furthermore, infrastructure, such as warehouses, storage equipment, and transportation fleets, requires ongoing maintenance and upgrades, which add to logistics costs.

By recognizing the factors that influence logistics costs, businesses can make more informed decisions, allowing them to identify areas where savings can be realized and make strategic adjustments to optimize their supply chain. Inspire Solutions provides the right tools to help you manage these factors, from warehousing and fulfillment to fast and reliable delivery.

Let’s move on to some practical ways you can reduce these costs and keep your operations efficient.

Read: CBM Meaning in Shipping Explained

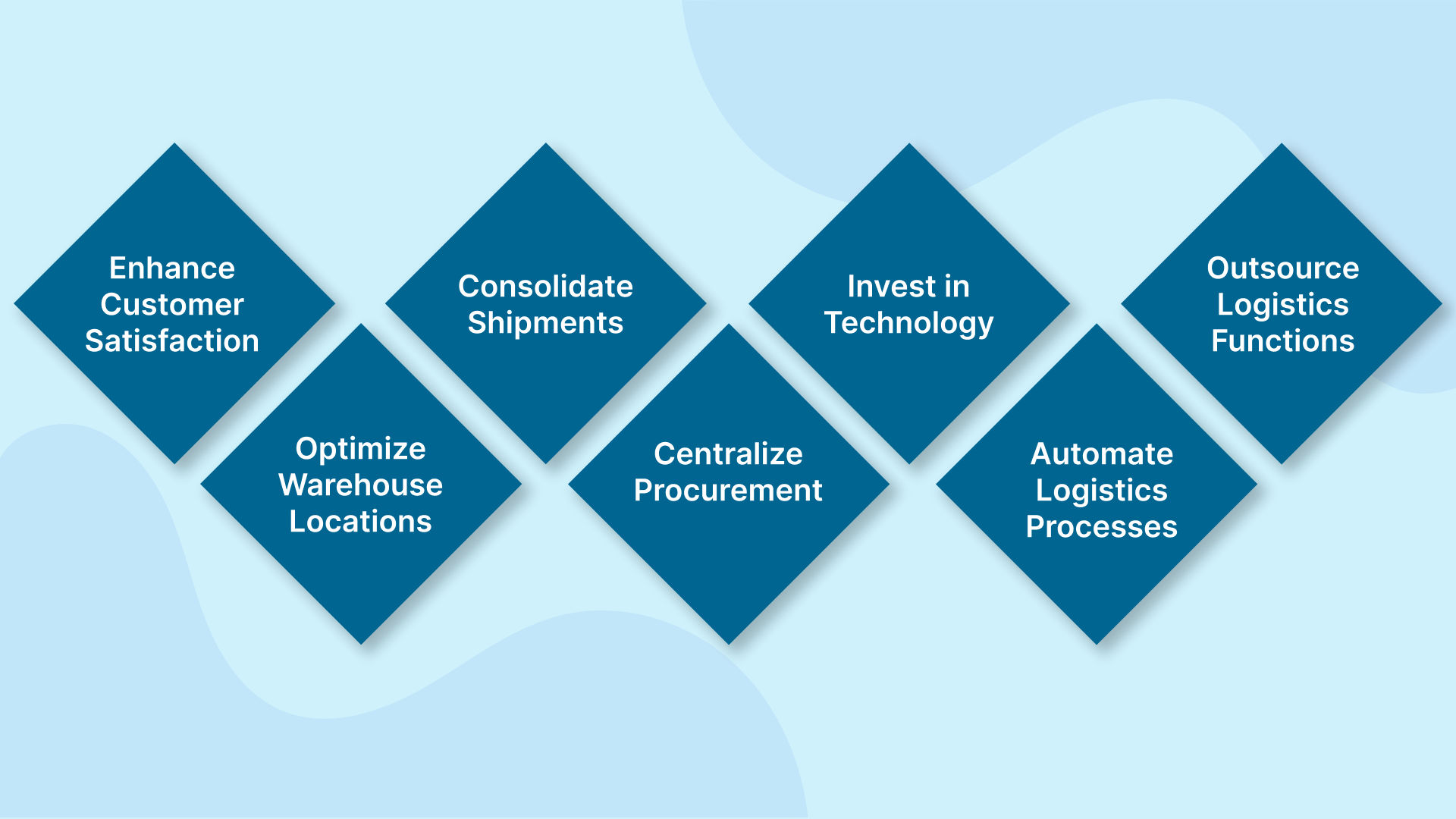

As businesses grow, so do the complexities and costs associated with their logistics operations. By focusing on optimizing core processes and leveraging strategic decisions, companies can not only reduce expenses but also enhance efficiency and customer experience without compromising service quality. Here are the major strategies that can be implemented:

1. Enhance Customer Satisfaction to Drive Cost Efficiency

Improving customer satisfaction is a practical yet often overlooked method to reduce logistics costs. Satisfied customers are more likely to return, minimizing marketing expenses and the need for extensive customer acquisition. This can also decrease last-minute shipping needs and enhance supply chain efficiency.

Cart abandonment, often caused by high shipping costs, significantly impacts customer satisfaction. Offering low-cost or free shipping can help alleviate this issue and encourage customers to complete their purchases. Additionally, increasing the Average Order Value (AOV) by offering free shipping for orders above a certain threshold or creating bundles can motivate customers to spend more, effectively covering shipping costs. These strategies ultimately lower customer acquisition costs and boost long-term profitability.

2. Minimize Delivery Distances by Optimizing Warehouse Locations

The proximity of your warehouse to customers has a significant impact on transportation costs. Shipping from distant locations raises expenses and prolongs delivery times. To reduce these costs, strategically locating warehouses near major customer bases is a practical approach. This results in faster delivery, lower costs, and higher customer satisfaction.

In areas without a physical presence, outsourcing to third-party logistics (3PL) providers with local warehouses can be transformative. This strategy decreases transportation and inventory costs while enhancing supply chain efficiency through quicker order processing and delivery. Ultimately, minimizing travel distances is vital for cost optimization and better customer service.

3. Consolidate Shipments to Cut Transportation Costs

Frequent, smaller shipments can increase transportation costs. Consolidating shipments into larger loads reduces these expenses. For example, grouping orders to the same destination maximizes truckload capacity, cutting fuel and labor costs. Additionally, consolidating from multiple suppliers limits the number of shipments to handle, further lowering costs. Batch processing orders into fewer shipments enables businesses to minimize logistics costs without compromising delivery speed or customer service, thereby streamlining the logistics process and ensuring timely deliveries.

4. Centralize Procurement to Lower Supply Chain Costs

Centralizing procurement is an effective strategy to reduce supply chain costs. By consolidating purchasing decisions and leveraging greater buying power, businesses can negotiate better terms with suppliers, obtain volume discounts, and streamline procurement processes. Separately, sourcing materials from nearby suppliers can further reduce transportation costs, decrease lead times, and lower stockout risks, providing additional geographic advantages for supply chain efficiency.

Additionally, centralizing procurement allows for volume purchasing. Buying materials in bulk often leads to lower unit prices and reduces overall costs. This strategy decreases order frequency and procurement expenses, enhancing logistics efficiency. Overall, centralized procurement not only cuts logistics costs but also improves operational efficiency.

5. Invest in Technology for Real-Time Data

Investing in technology is crucial for optimizing logistics and making data-driven decisions to cut costs. Real-time data is crucial for monitoring various phases of the supply chain. A Warehouse Management System (WMS) tracks inventory, optimizes storage, and enhances order accuracy, resulting in significant savings. Similarly, a Transportation Management System (TMS) optimizes routes, enhances fleet management, and reduces freight costs. Together, these technologies provide valuable insights for making proactive decisions that boost efficiency, minimize waste, and streamline operations, enabling businesses to identify and address inefficiencies and quickly reduce logistics costs.

6. Automate Logistics Processes to Improve Efficiency

Automation is integral for reducing logistics costs by improving efficiency and minimizing human error. Automated storage and retrieval systems (ASRS), picking robotics, and conveyor belts enhance order fulfillment speed and accuracy in warehouses, enabling higher order volumes without incurring increased labor costs.

Shipping automation, including automated packing and shipping systems, is crucial for reducing logistics expenses. These systems reduce errors, expedite order processing, and lessen manual input, addressing operational inefficiencies. Investing in automation not only boosts logistics efficiency but lowers overhead costs, enabling businesses to scale while maintaining service quality.

7. Outsource Logistics Functions to Third-Party Providers (3PLs)

Outsourcing logistics to a trusted third-party provider (3PL) can yield immediate cost reductions, particularly for complex or rapidly growing operations. 3PLs leverage their larger-scale operations to offer competitive shipping, warehousing, and fulfillment rates, thanks to their established infrastructure and economies of scale.

Besides cost savings, 3PLs offer specialized expertise and technology, which optimize supply chains and reduce inefficiencies. By outsourcing logistics, businesses can focus on core operations while enjoying the benefits of larger-scale cost savings. Utilizing experienced 3PLs ensures efficient logistics without the need for costly internal systems or expanding in-house operations.

Now, let’s discuss why choosing the right partner, like Inspire Solutions, can make all the difference in your logistics journey in the Philippines.

Inspire Solutions is the partner you need to make your e-commerce business run smoothly. They provide everything from warehousing and order fulfillment to fast delivery and financing, all in one place. Whether you’re just starting out or already established, they’ve got the tools to help you keep costs down, speed up your processes, and improve how you serve your customers. With flexible payment options and fast delivery times, they make sure your business can grow without any hurdles.

Logistics doesn’t have to be complicated. With the right support, you can lower your costs and make everything work more smoothly. Inspire Solutions offers just that: a simple, reliable way to manage your e-commerce operations, from warehousing to delivery. If you’re looking to take your business to the next level without dealing with extra complexity, Inspire Solutions can help.

Get in touch today and see how they can make a difference for your business.