Are you moving large volumes of raw materials but finding delays and rising costs cutting into your margins?

When transporting unpackaged goods, such as grains, ores, and fuels, in large quantities, specialized handling methods are required. In fact, proper management ensures cost-effectiveness, smooth operations, and timely delivery.

Philippines port-based shipments rose 10.5% to 65.77 million MT, straining operations due to inland transport and handling inefficiencies. As a result, this is causing increased strain due to inefficiencies in handling and inland transport. Your bulk cargo strategy shouldn’t be just about booking freight; it’s about complete visibility and coordination across sourcing, storage, and delivery.

Bulk cargo refers to unpackaged goods, including grains, ores, and fuels, that are transported in bulk quantities. You handle these transported items in large quantities without containers or pallets, which requires specialized handling methods. These materials are loaded, stored, and discharged directly into the cargo holds of ships, trucks, railcars, or barges. Equipment such as grabs, conveyors, or pumps is typically used for handling.

Bulk shipping efficiently supplies manufacturing plants, mills, and distribution centers with large volumes of commodities across diverse locations. With proper handling, you can ensure smooth operations across your supply chain and avoid product loss or damage during transit.

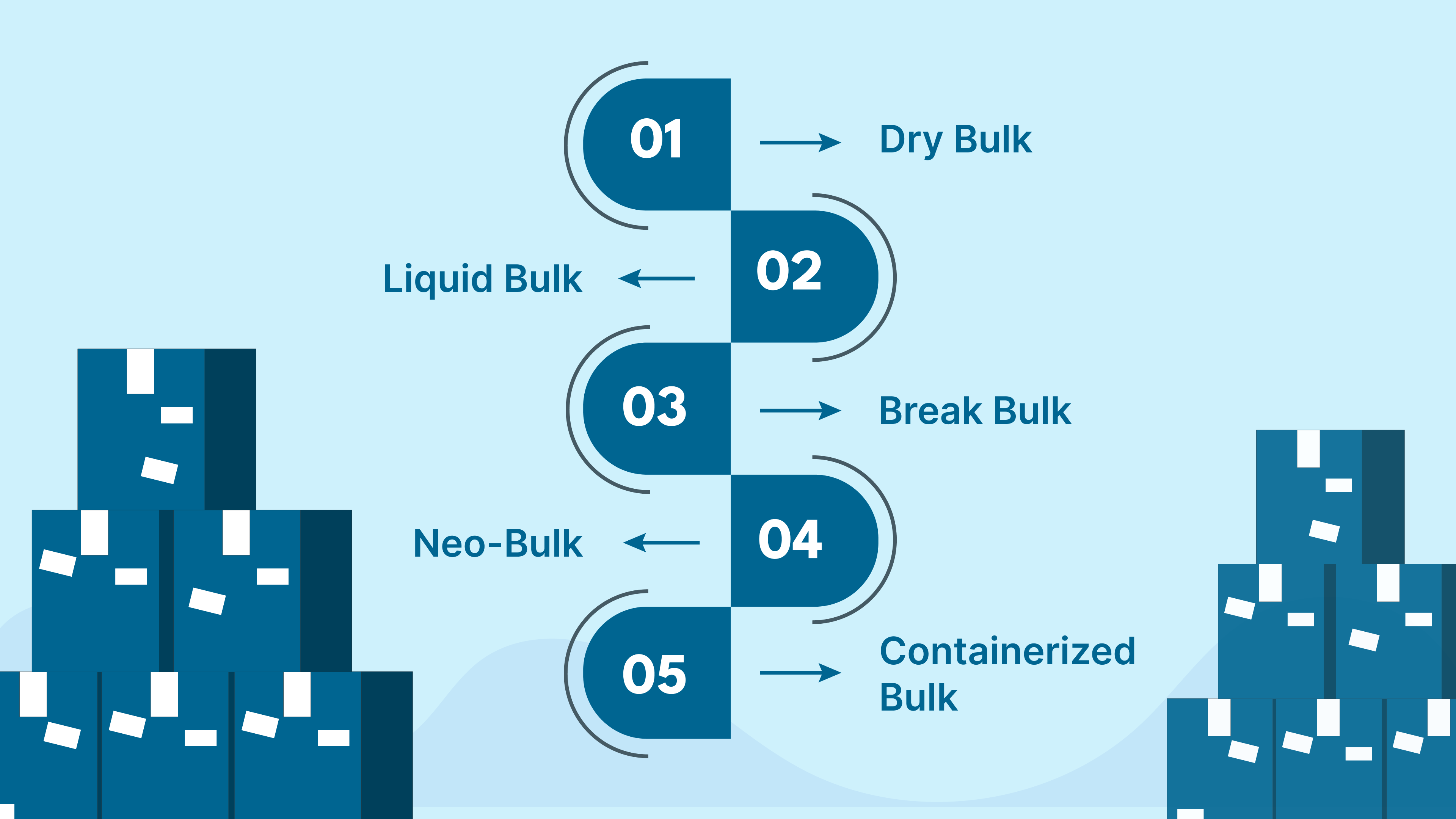

Having defined bulk cargo, next we’ll look at the different types of bulk cargo and the key features that distinguish them.

Bulk commodities are categorized into several distinct groups based on their physical form and handling requirements. Understanding the differences helps you choose the correct logistics setup and equipment for efficient movement and storage.

Dry bulk cargo refers to unpackaged, granular, or powdered materials, including coal, cement, rice, sugar, and nickel ore. These commodities are typically loaded directly into a vessel’s hold or bulk container using conveyors, hoppers, or grabs. In the Philippine context, dry bulk plays a major role in agriculture, construction, and mining supply chains.

Liquid bulk consists of free-flowing substances, such as crude oil, palm oil, liquefied natural gas (LNG), and various chemicals. These are shipped in tankers, ISO tanks, or flexitanks depending on volume and transport mode. Liquid bulk handling requires strict controls to prevent leaks, contamination, or regulatory violations, especially at major ports such as Batangas or Davao.

Break bulk refers to large, individually handled items such as industrial machinery, project cargo, or steel beams. These goods are not containerized and require lifting equipment, such as cranes and forklifts. This method is suitable for oversized or irregularly shaped cargo that can’t fit into standard containers.

Neo-bulk cargo includes pre-packaged, uniform goods moved in large quantities, such as vehicles, bundled steel, or logs, which allows for faster handling and more efficient logistics planning. While similar to break bulk, neo-bulk cargo is more standardized, allowing for quicker handling and easier planning. Dedicated terminals and roll-on/roll-off vessels are commonly used.

Containerized bulk involves dry or liquid commodities packed into containers equipped with liners, bulk boxes, or flexitanks. This format is ideal for intermodal transport, offering better protection against contamination and weather exposure. It’s increasingly popular in short-sea shipping across Southeast Asia for cost and operational flexibility.

Streamline your bulk logistics from source to port with full visibility

Talk to Inspire Solutions Asia TodayMoving forward, let’s examine the specialized containers that facilitate the transportation of these goods.

Also read: How to Reduce Logistics Costs: Effective Strategies

Bulk cargo is typically transported using specialized container types designed to match the characteristics of each commodity, offering practical solutions to minimize spillage, contamination, and manual handling while maintaining cargo quality throughout the supply chain.

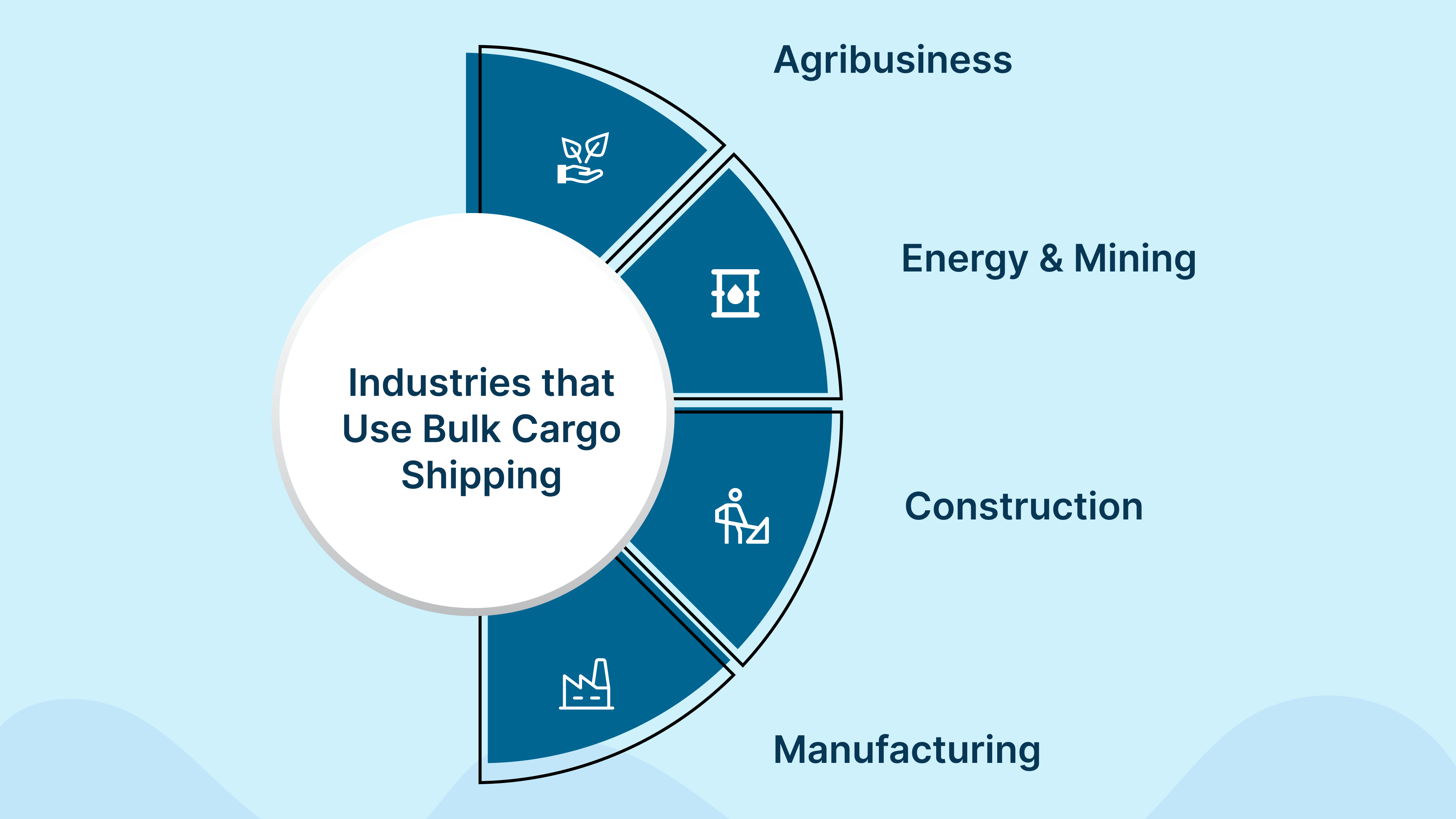

But how does bulk cargo move beyond just containers? The industries relying on this shipping method will provide insight into the widespread use of this method across various sectors.

If you operate in a sector that involves the transportation of large quantities of raw materials or industrial goods, bulk cargo shipping likely plays a central role in your logistics. Below are the primary industries that rely heavily on this method.

Now, let’s proceed to examine the logistics of handling shipments efficiently from start to finish.

Also read: Essential Shipping Documents for Import and Export

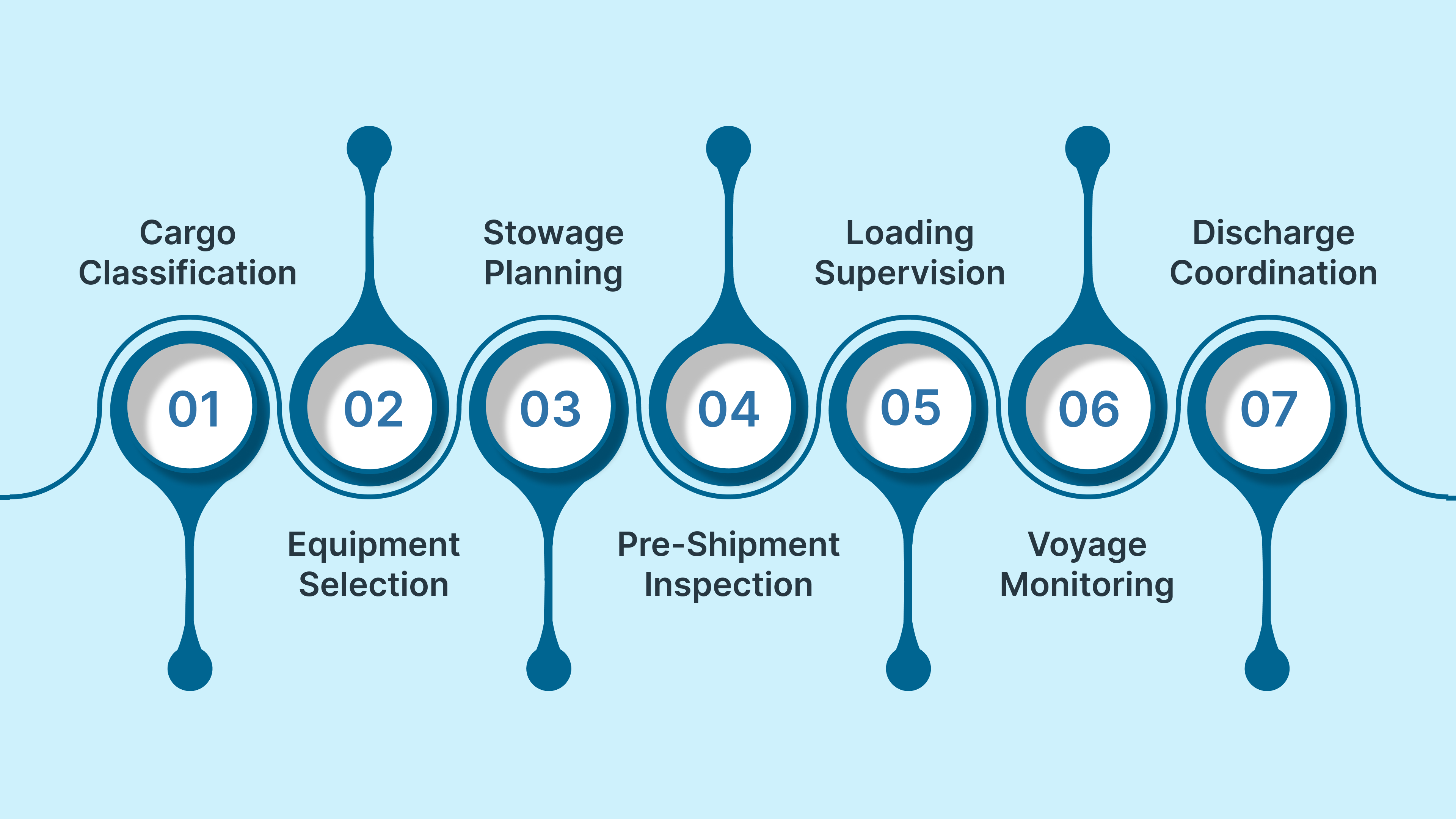

Handling bulk cargo requires careful planning to avoid damage, delays, and extra costs. Proper management ensures safe, timely delivery and smooth operations. Here are the essential steps for efficiently managing bulk cargo shipments. The following process helps you maintain control throughout the shipping cycle:

Start by accurately classifying your cargo. Confirm the correct commodity code, hazard class (if applicable), and any moisture content limits. This ensures compliance with port and maritime regulations, thereby avoiding delays in customs clearance.

Select the appropriate handling equipment based on the nature of your cargo. Grabs, hoppers, or pumps should match your material type and required discharge rate. Choosing the right equipment minimizes handling time and prevents material loss.

Plan the layout of the cargo in your container or vessel hold to prevent shifting during transit. Improper stowage can result in cargo damage, contamination, or stability issues during rough seas.

Inspect cargo conditions before loading. Check for moisture content, density, and ensure the cleanliness of storage holds or containers. This step reduces the risk of contamination or cargo rejection at the destination.

Monitor the loading process closely. Ensure cargo is evenly trimmed, perform draft surveys as needed, and record moisture levels as required. Accurate documentation here protects you in case of disputes or claims.

During transit, monitor critical factors such as weather conditions, cargo temperature, and hatch sealing to ensure optimal conditions are maintained. Real-time tracking can alert you to issues before they escalate.

Coordinate the discharge process ahead of vessel arrival. Align port schedules with inland transport availability to minimize wait times and avoid unnecessary demurrage charges. Efficient coordination helps you maintain service consistency and cost control.

Managing bulk cargo shipments requires attention to detail at every stage to ensure a seamless process. Having covered cargo handling, we’ll now discuss the various factors influencing bulk cargo shipping costs and how to manage them.

Get expert guidance from Inspire Solutions Asia to reduce cost shocks and manage bulk shipping budgets with confidence.

Contact Us Now

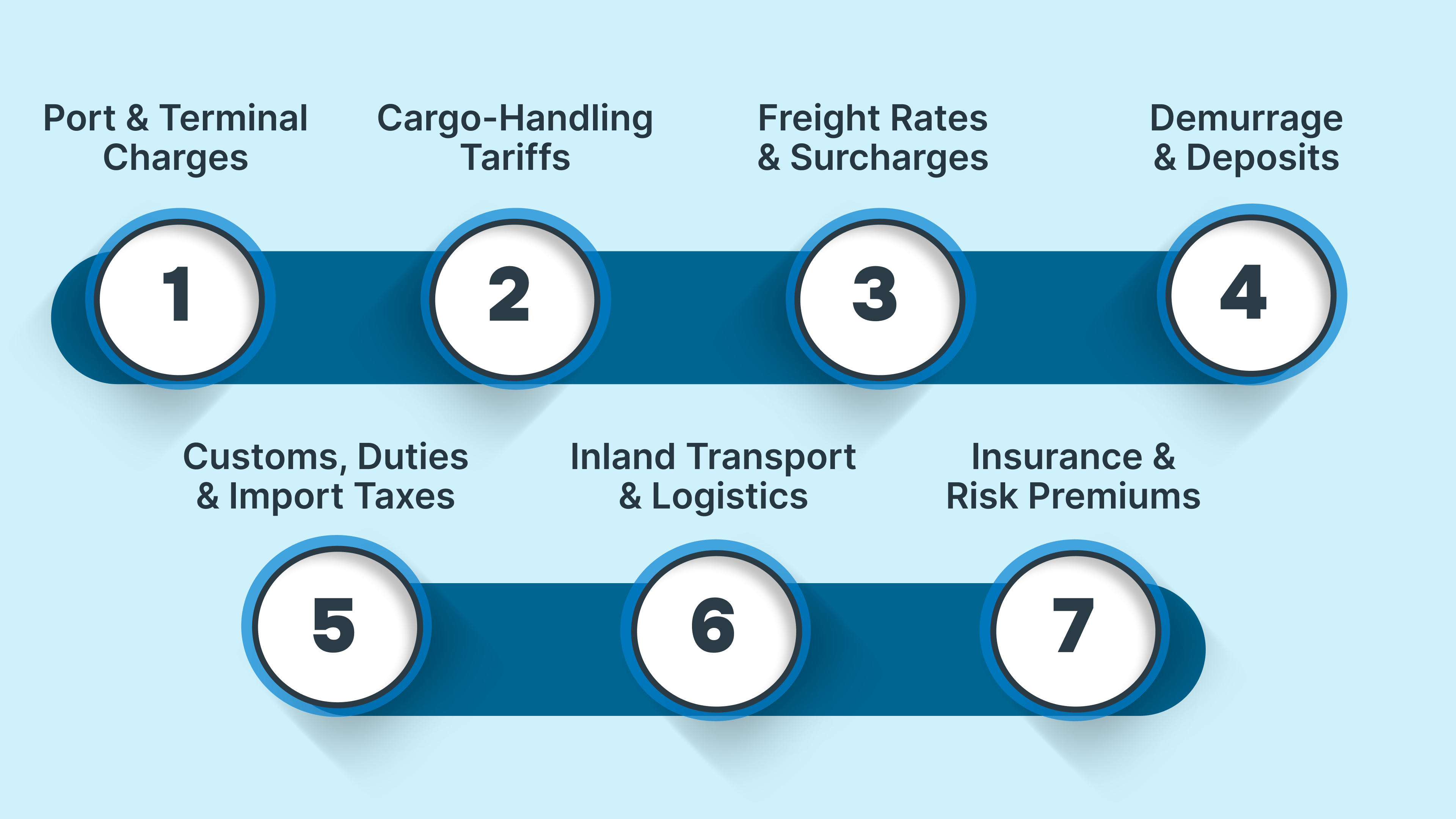

Understanding all the cost elements involved helps you accurately forecast and optimize your logistics expenses. These are the main factors you should monitor:

Port handling costs form a foundational part of your logistics spend. These include fees for cargo unloading, storage, and other dockside operations.

Rising terminal fees can impact your margins, especially in high-volume operations.

Your base freight rate is just one part of the total costs. Add-ons such as fuel surcharges, peak season charges, and currency adjustments can significantly increase your landed cost.

Delays at the port, whether caused by congestion or missed transport windows, can result in substantial penalties.

Import duties and VAT are calculated based on the CIF (Cost, Insurance, and Freight) value of your cargo. Misclassification or under-declaration can result in penalties or delays.

Insuring bulk cargo, especially hazardous materials or moisture-sensitive goods, adds a layer of expense.

Monitoring each of these components will help you optimize your bulk cargo budget and avoid hidden expenses. With this outlined, it’s time to look at best practices that help manage risks and keep operations running smoothly.

Also read: Understanding ASN: Advanced Shipping Notice Explained

Adopting the proper operational practices ensures your bulk cargo moves efficiently, remains protected, and complies with applicable regulations. The recommendations below help you reduce risks, avoid costly delays, and maintain shipment integrity from origin to destination.

Always classify your cargo accurately before shipping to ensure accurate delivery. Identify the correct IMO class, UN number (for hazardous goods), and the applicable Philippine tariff codes. This avoids delays during customs clearance and protects you from penalties or re-inspection costs.

Plan discharge before vessel arrival. Sync port schedules with inland transport to prevent delays and costly demurrage fees. This minimizes dwell time at the port and ensures cargo moves directly to its destination without bottlenecks.

Implement strict quality checks before loading. Conduct sampling, testing, and certification for moisture content, contamination, or other quality parameters. This is especially critical for commodities like grains, chemicals, or ores where condition on arrival can affect market value or acceptability.

Follow the rules set by relevant government agencies, including MARINA, the Philippine Ports Authority (PPA), and the Bureau of Customs. Staying up to date with circulars and clearance requirements reduces the risk of shipment holds and non-compliance issues.

Establish clear lines of communication among all stakeholders, including shippers, freight forwarders, port agents, and finance partners. Use shared digital dashboards or platforms to track progress, exchange documents, and minimize last-minute coordination errors.

Secure comprehensive marine insurance that covers the full value of your cargo against loss, damage, or delay. If you’re operating on volatile trade lanes, consider hedging freight rates to avoid seasonal or market-driven surges that could impact your cost forecast.

Building on these best practices, let’s discuss how you can elevate your bulk shipping and logistics operations. To achieve the next level, we aim for smoother and more predictable outcomes with partners like Inspire Solutions Asia.

Handling bulk cargo in the Philippines involves more than just port-to-warehouse transfers. You need full visibility and control across transport, storage, and delivery to avoid delays, reduce costs, and ensure consistency. When freight, fulfillment, and financing operate in silos, inefficiencies multiply quickly.

That’s where an integrated logistics model, like Inspire Solutions Asia, makes a difference by connecting sourcing, importation, warehousing, and last-mile delivery efficiently. Scaling imports or expanding products? Inspire’s sourcing ensures smooth procurement, regulatory compliance, and consistent operations across your supply chain.

These services ensure regulatory compliance and smooth importation, supporting operational consistency at every stage. To better meet growing customer expectations, consider Inspire’s fulfillment solutions, designed for speed, accuracy, and nationwide reach. To strengthen your end-to-end supply chain, explore integrated warehousing options tailored to bulk cargo logistics. This provides operational flexibility and scalability, enabling efficient growth and smoother fulfillment across your network.

Simplify logistics, reduce overhead, access financing, and enable fast delivery with Inspire Solutions Asia, your digital commerce partner.

Request a consultation today.Bulk cargo is handled using various equipment based on the type of cargo. Common methods include conveyor belts, cranes, grab buckets, pipelines, and tankers. For dry bulk, hoppers and grab cranes are used, while liquid bulk is transferred using pipelines or tankers.

The three main types of bulk cargo are dry bulk (like coal, grain, and ores), liquid bulk (such as crude oil, chemicals, and water), and gas bulk (like liquefied petroleum gas or LNG).

Cargo handling involves loading the cargo, securing it to prevent damage, transporting it, unloading, and completing necessary documentation or inspections.

Bulk cargo can be calculated by its weight (tonnage) or volume (cubic meters). Volume is calculated by measuring the space it occupies and considering its density, or the cargo can be weighed directly.

To calculate cubic meters (m³) for cargo, measure the length, width, and height of the cargo, then multiply these dimensions (L x W x H) to get the volume in cubic meters. For irregular shapes, approximate or use specialized methods.