What drives a business to rethink how it manages every item on the shelf, every parcel in transit, and every order promised to a customer?

In the Philippines, e-commerce and logistics are moving at a pace that demands sharper tools and more innovative processes. The country’s freight and logistics market is projected to grow at an annual rate of 8.10%, reaching nearly PHP 41.75 billion by 2034. Meanwhile, total real trade is expected to increase by 4.5% year-on-year in 2025. These numbers signal a surge in demand, tighter delivery windows, and more pressure to keep stock moving without error. Businesses that lack clear, reliable systems for tracking inventory risk are falling behind not just in speed, but in accuracy and customer trust. We understand how stressful it can be to juggle inventory accuracy, tight delivery schedules, and growing customer demands simultaneously.

This blog explains how the right inventory tags and labels can help your business stay ahead, minimize errors, and remain prepared for what’s next.

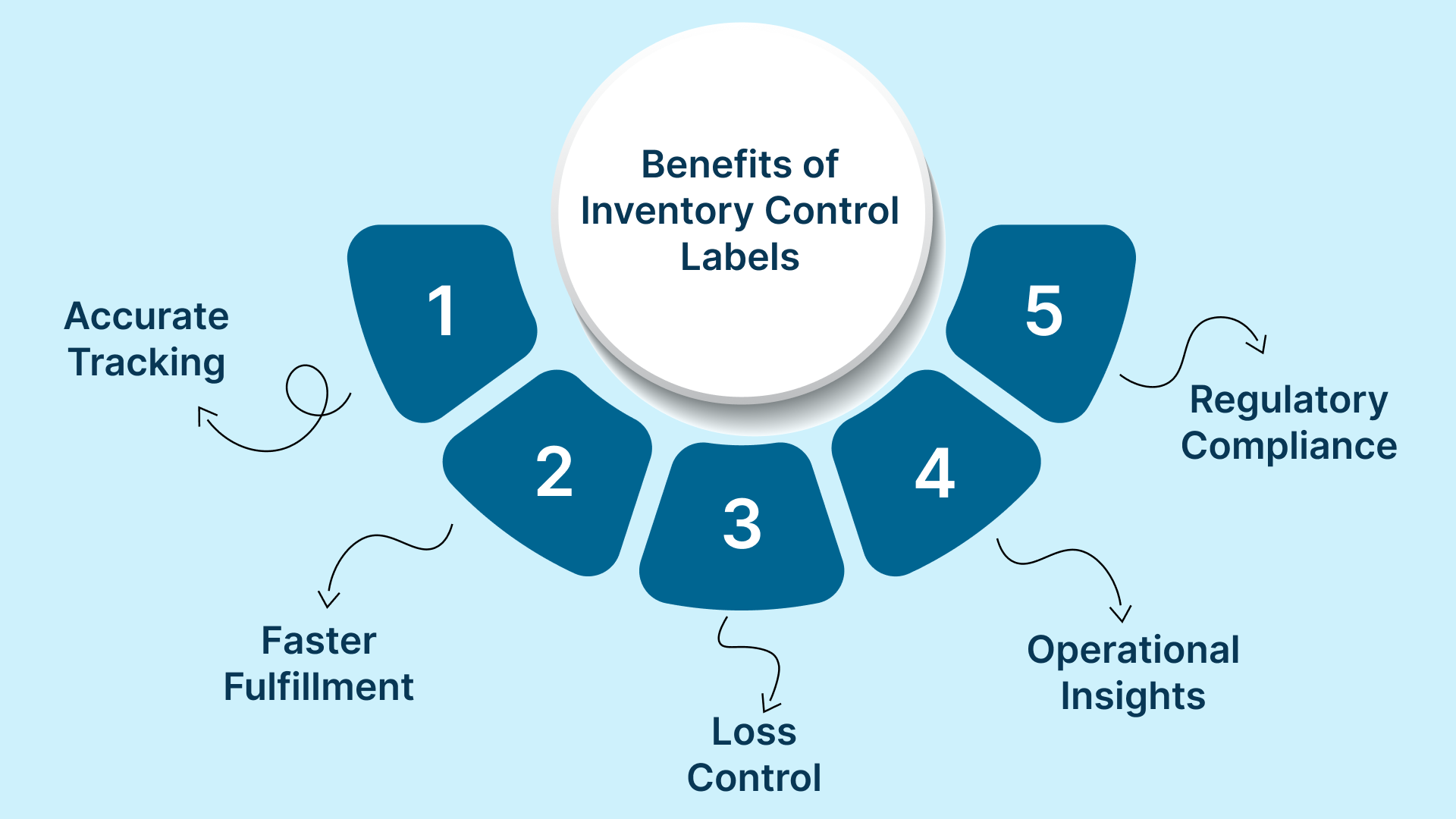

A strong labeling system doesn’t just organize your stockroom; it delivers real, measurable impact across your operations. Here’s how inventory labels directly improve your day-to-day business:

When every SKU is appropriately tagged, your inventory records align with what’s actually on the shelf, providing better visibility that allows you to respond quickly to demand shifts, minimize costly mistakes, and maintain smooth fulfillment. As the Philippines market is expected to grow at a CAGR of 6.30%, that level of accuracy also protects your reputation on online marketplaces, helping you steer clear of penalties or missed SLAs.

Instead of searching for items by eye, your team can rely on labels to speed up picking and packing. Scanning reduces errors and shortens travel paths, allowing you to meet tight delivery windows, such as same-day or next-day shipping. With fewer delays, you can accomplish more in less time, redirecting saved hours to strategic work instead of repetitive tasks.

With serialized tags in place, every product movement is traceable. If something goes missing, you can use scan history to pinpoint where and when it happened, whether it’s a mispick, misplacement, or theft. By catching shrinkage early, you prevent small losses from accumulating into significant profit drains.

Your scan data is processed in real-time to generate dashboards that highlight fast-moving and slow-selling items, enabling informed stock adjustments and promotions. You can adjust stock levels, bundle offers, or restock fast movers more confidently because you’re acting on live insights, not guesswork. Over time, this helps you build a leaner, more innovative inventory model.

If your business handles regulated goods or international shipments, labeling gives you built-in compliance. Each scan creates a verifiable trail for customs and auditors, showing where an item came from, how it was stored, and where it’s headed. You won’t need to scramble for records; the data is already captured in your daily flow.

With these direct benefits of inventory labels, it’s clear that the right label system offers more than just basic stock organization. However, before you decide which type of labels best suits your needs, it’s essential to understand the various types available.

Also Read: Key Advantages of Inventory Management Systems

No single label fits every workflow. Your best choice depends on the number of orders you handle, the value of your inventory, and the rate of your growth. By aligning label type with your operations, you keep costs low while maintaining scan speed and reliability.

Here are the most common types, and where they fit best in your setup:

Knowing how to implement them is equally important; hence, let’s shift gears and look at best practices to ensure your labels deliver maximum value.

Even the best-designed label won’t deliver results if it’s poorly applied or inconsistently maintained; following best practices ensures your inventory remains accurate and your tagging system scales effectively during peak demand.

To avoid scan errors and delays, your labels need to be placed in a uniform, predictable location. Here’s how you can maintain placement consistency across all products:

Periodic checks ensure your labels stay readable and functional. Use the following audit practices to keep your system clean and accurate:

Even experienced staff benefit from quick refreshers. These training tips will help your team stay efficient and avoid mistakes during scanning:

Tropical conditions and heavy handling demand stronger materials. Use these guidelines to make sure your labels last as long as your products do:

Your labeling system should communicate with your software in real-time. These integration steps ensure your scans are always accurate and actionable:

By incorporating these best practices into your daily operations, you can maximize the value of your inventory labels. But designing and printing those labels is another step. Next, let’s go over the process of creating labels that are both effective and durable.

Also read: Effective Inventory Optimization Techniques and Strategies

Designing dependable inventory labels isn’t difficult, but skipping a key step can lead to costly delays, mis-picks, or failed returns. To avoid problems down the line, you need a structured process that ensures each label is accurate, durable, and scannable from day one. Here’s a four-step framework to help you create consistent, scan-ready labels that work across your operation:

Begin by deciding exactly what information needs to appear on each label. Include essentials such as SKU, product name, size, batch number, or expiry date, as well as any other information your team or scanner needs to process the item efficiently. Keep the content focused so you avoid clutter while ensuring accurate reads on every scan.

Select a label format that suits your operational requirements and budget. Barcodes are a reliable and cost-effective option for most businesses. If you need to scan items in bulk or through packaging, go for RFID. Want to give customers or team members access to rich product info? Use QR codes to link to manuals, specifications, or usage guides.

Make your labels easy to scan at a glance. Use high-contrast fonts that are at least 8 points in size, and leave sufficient white space around barcodes or QR codes to prevent misreads. Consistency is key; placing elements in the same position on every label helps your team scan faster, especially during peak hours.

Match your printing setup to the number of labels you’ll need daily. For small batches or pilot runs, a 300-dpi desktop printer will suffice. For high-volume environments, invest in industrial printers equipped with auto-cutters that can operate continuously. And always stock extra ribbons or thermal paper to avoid downtime when you need to print urgently.

Creating labels with this level of detail will ensure they work effectively throughout your operations. Next, let’s examine how various industries benefit from a robust inventory tagging strategy.

If your business involves moving physical products, inventory labeling offers immediate value. But in specific industries, the payoff is exceptionally high, whether through faster operations, better compliance, or both. Here’s how your sector might benefit:

As your business grows, simple barcode systems may no longer meet your needs. Let’s take a look at more advanced inventory tagging techniques that can keep up with increasing demands.

Also Read: Improving Stock Control Systems: Methods and Best Practices

As your order volume grows, basic barcode setups can start slowing you down. Here are three scalable tagging techniques that help you move faster without adding more hands to the floor:

Also read: Comprehensive Guide to Finished Goods Inventory Management

With these advanced techniques in your toolkit, you can confidently scale your operations without sacrificing efficiency or accuracy. Strong inventory control begins with something as simple as labeling, but its impact extends to every part of your operation. With accurate tracking, faster fulfillment, and data-driven decision-making, you position your business to compete and grow in an increasingly digital world.

But labels are just the beginning. When paired with a connected backend, innovative warehousing, reliable delivery, flexible financing, and streamlined sourcing, you don’t just improve your stockroom; you also enhance your entire supply chain. You transform your entire e-commerce engine.

That’s where we come in.

Inspire Solutions Asia helps you remove friction from daily operations, enabling you to scale with confidence. Here’s what you can count on:

Ready to take the next step? Book a free consultation to see how seamlessly integrated operations can change the way you do business.

Let’s simplify your logistics and unlock your full growth potential.