How do you reduce warehousing costs while keeping fulfillment fast, accurate, and scalable?

With e-commerce growing rapidly, warehouse efficiency is more important than ever. Rising costs and higher customer expectations are making traditional warehouse setups harder to rely on. This is where lean warehouse practices offer a proven framework to eliminate waste, improve flow, and drive better results across the supply chain.

The ASEAN Warehousing and Distribution Logistics Market size is estimated at USD 33.04 billion in 2025 and is expected to reach USD 42.78 billion by 2030, at a CAGR of 5.3% during the forecast period (2025-2030). This growth highlights the increasing importance of optimizing warehouse operations and embracing efficient, scalable practices to stay competitive in the fast-evolving logistics landscape.

In this article, we’ll explore the key benefits of lean warehousing, the core principles behind it, and best practices to implement in your warehouse to optimize operations.

Lean warehouse practices are derived from lean manufacturing principles, originally developed by Toyota to eliminate waste and optimize processes. In warehousing, these practices focus on reducing inefficiencies, such as unnecessary movement of goods, overstocking, and redundant tasks in order fulfillment.

Key aspects of lean warehouse practices include optimizing warehouse space, aligning inventory levels with actual demand through Just-in-Time (JIT) inventory, and utilizing automation and technologies like Warehouse Management Systems (WMS) and barcode scanning to streamline operations.

Also Read: What Is a Central Warehouse and Its Role in Logistics

Having explored the foundational aspects of lean warehouse practices, let’s dive into the key benefits of lean warehousing and how these practices can directly enhance your warehouse operations.

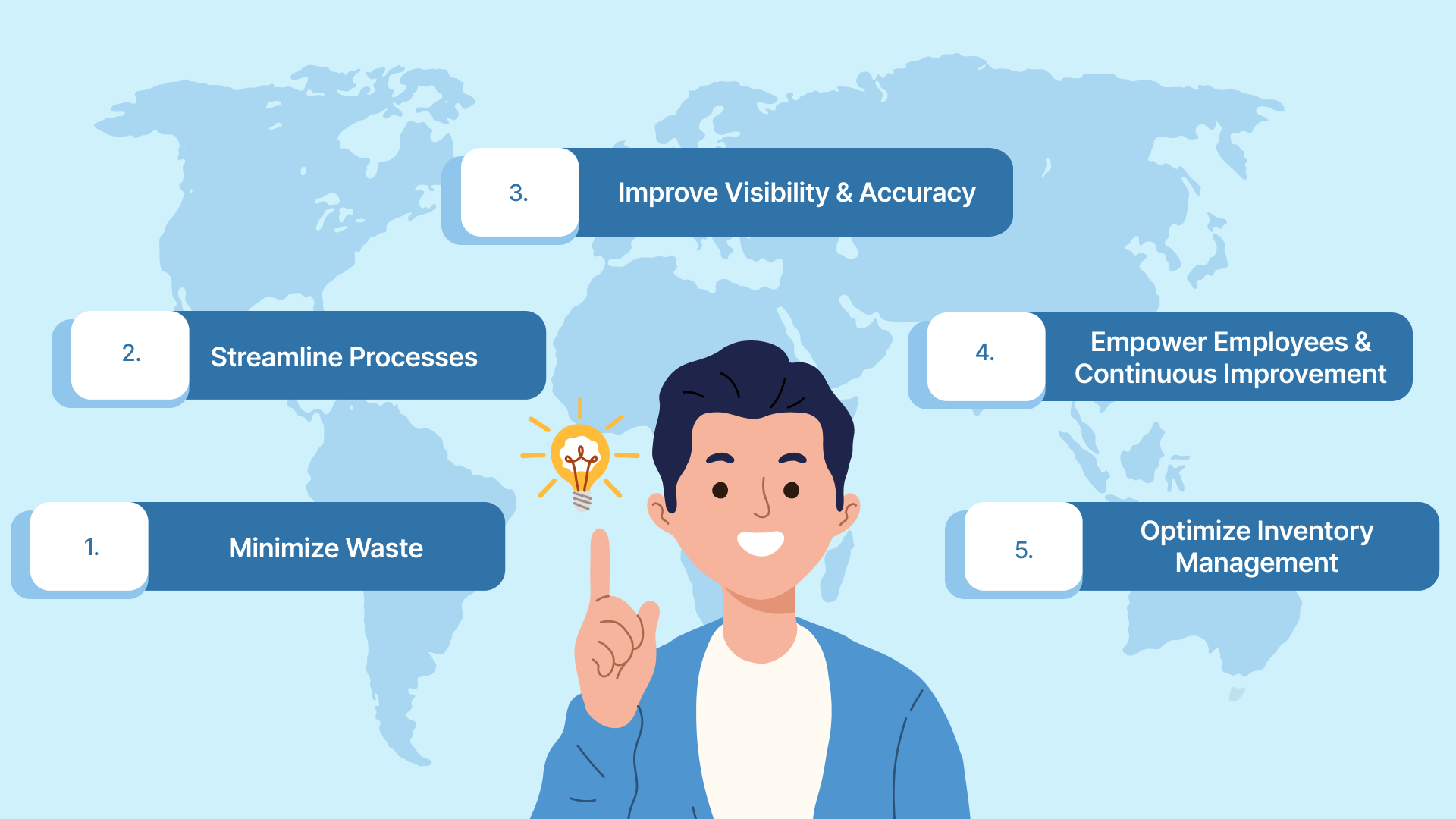

Implementing lean warehouse practices brings a multitude of benefits that directly enhance warehouse operations, from improving efficiency to reducing costs. By optimizing workflows and eliminating waste, businesses can achieve better overall performance. Here are some key benefits:

Lean practices streamline warehouse operations by eliminating wasteful activities. This helps reduce cycle times, minimize unnecessary handling, and ensure a more consistent flow of goods. As a result, warehouse staff can complete tasks more efficiently, leading to increased overall productivity.

Lean warehousing directly impacts costs by reducing excess inventory, unnecessary storage space, and manual labor. For example, by adopting Just-in-Time (JIT) inventory management, businesses can minimize holding costs and optimize stock levels, reducing the need for large storage spaces and decreasing inventory-related expenses. A study shows that applying lean warehousing management can save up to 20%-50% of companies’ costs by optimizing inventory levels and improving warehouse operations.

Lean practices lead to faster order processing and fewer errors in fulfillment. With better-organized warehouses and improved workflows, businesses can offer quicker shipping times and higher order accuracy, both of which significantly enhance customer satisfaction and loyalty.

Efficient layout design and better inventory management ensure that warehouse space is used effectively. With proper organization, you can maximize storage capacity, reduce clutter, and avoid the need for expensive warehouse expansions. Optimized storage also reduces the risk of damage to goods and ensures safer working conditions.

Lean warehouses are more adaptable to changes in demand and unexpected disruptions. By incorporating flexible systems like automated picking and optimizing workflows, businesses can swiftly adjust to fluctuations in order volumes, enabling them to stay competitive in dynamic markets.

By understanding the core benefits, it’s clear that lean warehousing offers significant operational improvements. Now, let’s take a closer look at the guiding principles that make these benefits possible.

Ensure fast and reliable delivery to your customers with Inspire Solutions Asia‘s SameDay and NextDay services. We provide SameDay delivery within Metro Manila and select nearby areas, and NextDay delivery to other provinces across the Philippines. Schedule a meeting today to find out how we can manage your delivery process and ensure your products reach customers on time.

Lean warehouse practices are rooted in optimizing warehouse operations and eliminating waste. These practices aim to create smooth, efficient workflows that minimize inefficiencies while maximizing productivity. At the heart of lean warehousing are the 5S principles, which guide the process of creating a well-organized, productive environment. Below are the key lean warehousing principles, aligned with the 5S approach:

Waste in warehousing refers to any activity or resource consumption that doesn’t add value to the customer. This includes unnecessary movement, overstocking, or redundant tasks. The Sort (Seiri) principle addresses waste by identifying and removing unnecessary items from the warehouse, thereby streamlining operations and minimizing waste. By consolidating inventory and reducing unnecessary tasks, warehouses can operate more efficiently.

Streamlining processes focuses on improving the flow of goods and reducing unnecessary steps. The Streamline (Seiton) principle emphasizes organizing warehouse spaces so that items are stored logically and are easy to access. This reduces handling times, accelerates order fulfillment, and ensures smoother workflows. With fewer obstacles in the way, processes are faster, more efficient, and ultimately more productive.

In lean warehousing, it’s crucial to have visibility over inventory and accurate tracking of goods. This improves order accuracy and reduces errors. The Shine (Seiso) principle ties into this by advocating for a clean and organized warehouse environment. Regular cleaning and maintenance ensure that systems and processes run smoothly, preventing disruptions caused by clutter or malfunctioning equipment. This clarity improves both accuracy and efficiency, enhancing overall performance.

Lean warehousing thrives on the empowerment of employees to identify inefficiencies and suggest improvements. The Standardize (Seiketsu) principle ensures consistency across processes and practices. By establishing uniform standards and regular training, all staff members can effectively follow procedures, which in turn boosts productivity and reduces the chances of errors. Continuous feedback and improvement foster a culture of innovation and operational excellence.

Efficient inventory management is a cornerstone of lean warehousing. The Sustain (Shitsuke) principle is crucial here, ensuring that lean practices are maintained consistently. By adhering to standardized inventory practices, such as Just-in-Time (JIT) inventory and regular forecasting, businesses can minimize excess stock, reduce storage costs, and ensure they meet demand without overstocking. Sustainable, effective inventory practices keep warehouses agile, allowing them to adapt to fluctuations in demand.

Also Read: How to Track Inventory: Steps and Tips

Now that we’ve outlined the core principles of lean warehousing, it’s time to explore the best practices that can help bring these principles to life and optimize your warehouse operations even further.

Implementing lean warehouse practices requires not only understanding the principles but also applying them effectively in day-to-day operations. These best practices help ensure that lean strategies are not only implemented but also sustained over time.

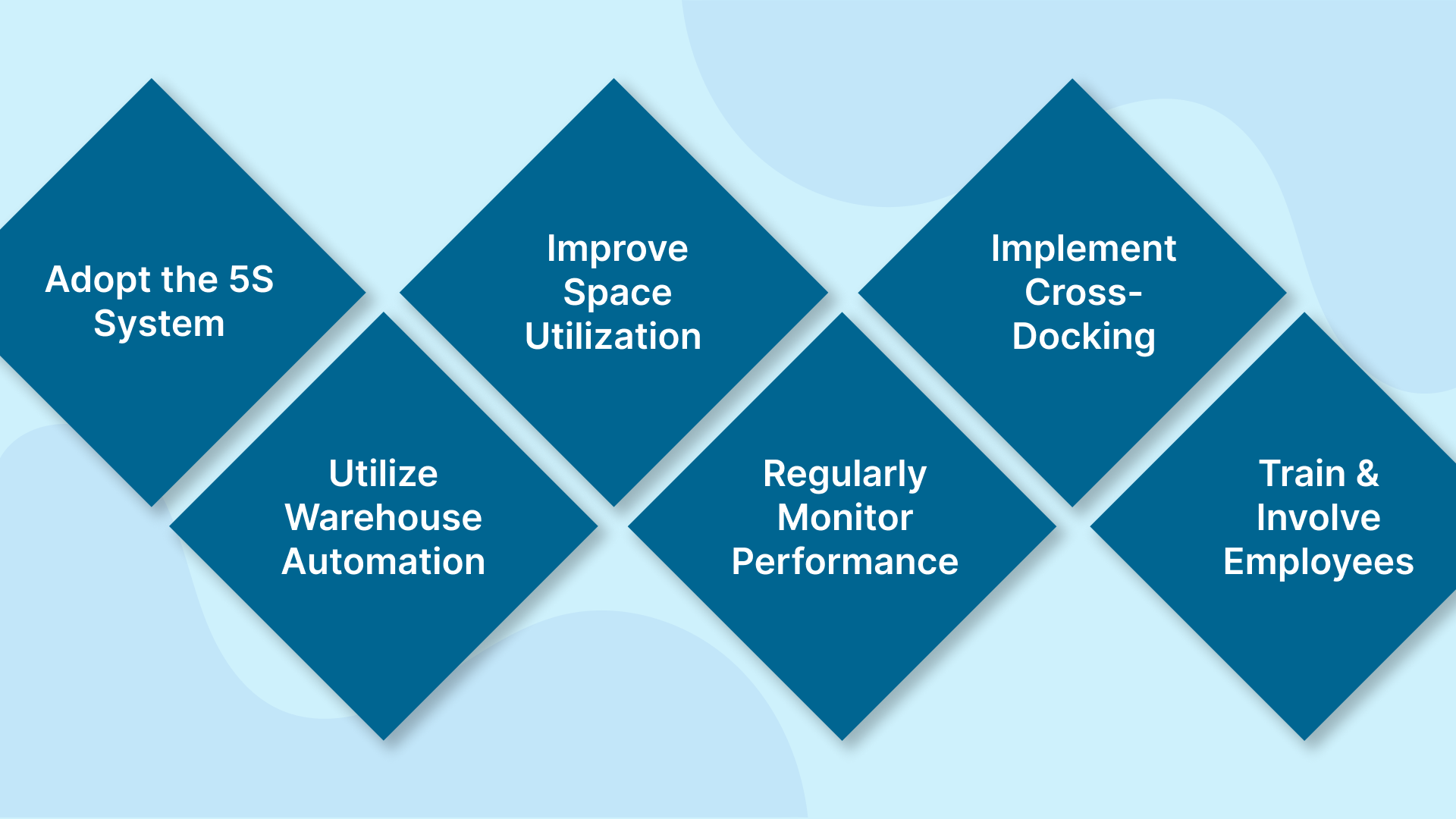

The 5S system, Sort, Streamline, Shine, Standardize, and Sustain, should be applied consistently across all warehouse areas to maintain organization, reduce waste, and support continuous improvement.

Implementing automation technologies like automated storage and retrieval systems (ASRS) and robotic picking systems can significantly increase picking speed and accuracy. These tools reduce manual labor, lower the risk of human error, and increase overall warehouse efficiency.

Optimize warehouse layout to reduce travel time and improve storage efficiency. Place high-demand items closer to the packing and shipping areas, and utilize vertical space for storage. Well-designed workflows reduce unnecessary movements and improve overall efficiency.

Continuously track key performance indicators (KPIs) such as order accuracy, picking speed, and inventory turnover. Monitoring performance allows warehouse managers to identify areas for improvement and ensure lean practices are being effectively maintained.

Cross-docking involves transferring goods directly from receiving to shipping, without the need for storage. This lean practice reduces handling times, cuts down on storage needs, and speeds up the order fulfillment process.

Training is essential for sustaining lean warehouse practices. Ensure that employees are familiar with lean principles like 5S and JIT inventory, and involve them in continuous improvement initiatives. When employees are empowered, they are more likely to identify areas for improvement and contribute to process optimization.

At Inspire Solutions Asia, we recognize that implementing and maintaining efficient warehouse operations can be challenging, particularly as businesses scale. With the rise of e-commerce, optimizing warehouse processes and reducing operational costs have become more crucial than ever. Lean warehousing practices can significantly enhance productivity, but managing the complexities of space, inventory, and processes requires the right tools and expertise.

Here’s how we can help you optimize your warehouse operations with lean practices:

Our expertise in warehousing can help your business achieve significant savings, improve operational efficiency, and enhance customer satisfaction. Want to optimize your logistics and minimize shipping costs? Contact Inspire Solutions Asia today to learn how we can help transform your business operations with our efficient logistics solutions.

Implementing lean warehouse practices is crucial for businesses looking to improve efficiency, reduce costs, and enhance customer satisfaction. By focusing on eliminating waste, optimizing processes, and involving employees in continuous improvement, businesses can create a more agile, productive, and cost-effective warehouse operation.

If you’re looking to implement lean practices in your warehouse, consider utilizing technology and following the best practices outlined above. By doing so, you’ll be able to stay competitive, reduce operational costs, and improve service levels, helping your business thrive in a fast-paced market.

At Inspire Solutions Asia, we specialize in simplifying logistics through customized warehousing, fulfillment, and shipping solutions. Our expertise helps businesses minimize costs and smooth operations, ensuring seamless supply chain performance.

Let us manage your shipping to better suit your business needs. Reach out for consultations, demos, or more information about our services.