How are businesses in the Philippines adapting to the growing demand for faster and more efficient logistics?

As commerce accelerates and consumer expectations rise, businesses are compelled to reevaluate their logistics strategies to remain competitive. In 2024, the gross value added from the transportation and storage sector reached approximately PHP 835 billion, reflecting a significant uptick from the previous year. This growth highlights the increasing demand for efficient logistics solutions. Moreover, with the warehousing segment projected to grow at around 9% annually through 2029, driven by the need for advanced storage and distribution solutions, businesses are under mounting pressure to optimize their logistics operations.

In this blog, we’ll take a closer look at how logistics facilities work, their impact on supply chain efficiency. As the industry evolves, understanding the role of logistics in business operations is essential for staying ahead in a competitive market.

A logistics facility is a designated space where goods are stored, processed, and distributed to meet the needs of a supply chain. It plays a crucial role in connecting manufacturers, retailers, and consumers by streamlining the flow of goods through various transportation modes, such as trucks, ships, and trains. These facilities are essential to ensuring products reach their final destinations on time, efficiently, and cost-effectively.

Let’s take a closer look at how logistics facilities operate and their role in the broader context of e-commerce success.

Logistics facilities come in different forms, each tailored to specific functions within the supply chain. From warehouses to fulfillment centers, each type plays a crucial role in managing the flow of goods, inventory, and orders, ensuring that businesses meet customer demand. Here is a breakdown of the different types and their respective roles in efficient logistics operations.

Each facility type plays a distinct role in optimizing the flow of goods, reducing the time and cost associated with getting products to the end customer. Now, we’ll examine the key features that make logistics facilities successful and what makes them a valuable asset to your business.

The success of logistics facilities depends on several key features that contribute to efficient operations, including strategic location, advanced technology, and stringent security measures. These aspects ensure that goods are stored and processed with the highest accuracy and speed, helping businesses meet the demands of a fast-paced marketplace. Here is an in-depth examination of the key components of a logistics facility.

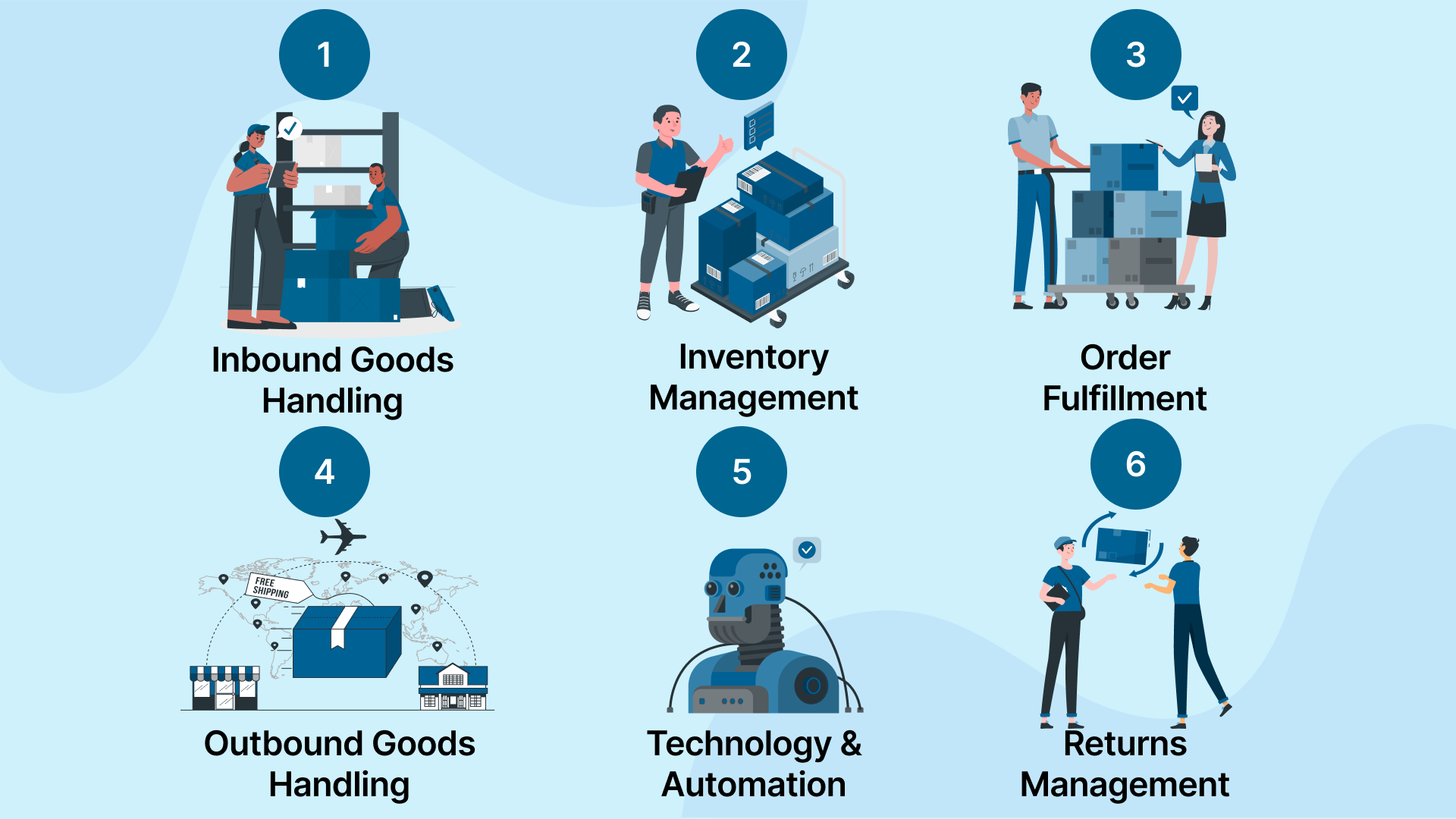

Logistics facilities operate as hubs where goods are received, stored, processed, and shipped to their final destinations. The core operations in these facilities revolve around ensuring that inventory is managed efficiently, orders are fulfilled on time, and products are securely distributed. Here’s how these facilities typically function:

The process begins with receiving products from suppliers or manufacturers. Upon arrival, goods are inspected, checked for quality, and recorded into the inventory system. The products are then sorted and stored in the designated areas within the facility according to their type, size, or handling requirements.

Inventory management is crucial for optimizing operations. Logistics facilities rely on Warehouse Management Systems (WMS) to track products in real-time. This system helps organize stock, monitors inventory levels, and automates reordering to ensure businesses never run out of critical products. RFID and barcode scanning technologies further streamline the process, making tracking and retrieval of items faster and more accurate.

Once an order is received, the picking and packing process begins. Workers or automated systems retrieve the products from storage, verify their accuracy, and prepare them for shipping. This step may include packaging goods in protective materials, labeling, and creating shipping documentation.

After an order is packed, it is loaded onto the appropriate transportation method, be it trucks, trains, or ships, for delivery. Logistics facilities must coordinate with multiple transport options to ensure that products are dispatched to customers quickly and at the lowest cost. Effective routing software plays a crucial role in optimizing delivery paths and minimizing transportation delays.

Many logistics facilities incorporate automation to streamline operations. Automated conveyors, robotic pickers, and sorting machines help reduce human error, increase operational speed, and lower labor costs. The integration of technology not only enhances inventory accuracy but also reduces processing times.

Logistics facilities also handle returns, which can be a complex part of the operation. A returns management system tracks returned goods, ensures they are processed correctly, and determines whether they will be restocked, repaired, or disposed of. Efficient returns management can significantly reduce operational costs and improve customer satisfaction.

Logistics facilities are essential for ensuring supply chain efficiency, as they coordinate processes such as inbound goods, order fulfillment, and transportation networks to deliver timely and cost-effective service. We will now examine how they enhance supply chain efficiency and the factors that drive their effectiveness.

A logistics facility plays a central role in optimizing the supply chain by ensuring goods are delivered quickly and cost-effectively. With the right technology and process design, these facilities significantly enhance delivery speed and reduce operating costs. Here is how logistics facilities influence the overall efficiency of supply chains.

Logistics facilities handle both the inbound and outbound flow of goods. This means receiving products from suppliers, storing them, and then shipping them to customers or retailers. Key transportation modes, including trucks, trains, and ships, are utilized to transport goods between these facilities and their respective destinations.

To streamline operations and enhance customer satisfaction, logistics facilities focus on several efficiency drivers:

Real-life examples of logistics facilities achieving high efficiency include faster order processing and reduced shipping delays, which contribute to an overall better customer experience. At Inspire Solutions, we integrate these efficiency drivers with innovative logistics technology and automation, ensuring that your business not only meets customer demands but exceeds expectations with faster, more reliable fulfillment and lower operational costs.

Let’s now explore some of the challenges logistics facilities face and how these obstacles can be managed.

Read: Supply Chain Examples and Effective Strategies Explained

Logistics facilities are committed to ensuring the safe distribution of goods, focusing on both secure storage and proper handling during transportation. This not only prevents product damage but also maintains the integrity of the goods being shipped. Here are the key safety practices logistics facilities employ to ensure secure distribution:

To protect goods, logistics facilities implement various safety protocols:

To reduce the risk of damage during distribution, logistics facilities rely on:

Adhering to safety standards and regulations in logistics is critical, particularly those set by local authorities such as the Department of Labor and Employment (DOLE) and the Department of Transportation (DOTr) in the Philippines. Compliance with these regulations ensures a safe work environment, improves operational efficiency, and minimizes the risk of penalties, delays, and unplanned costs. Failing to meet these standards can lead to severe operational disruptions and additional expenses, making compliance a cornerstone of successful logistics operations.

Now, let’s take a closer look at the key challenges logistics facilities face and how to manage these issues.

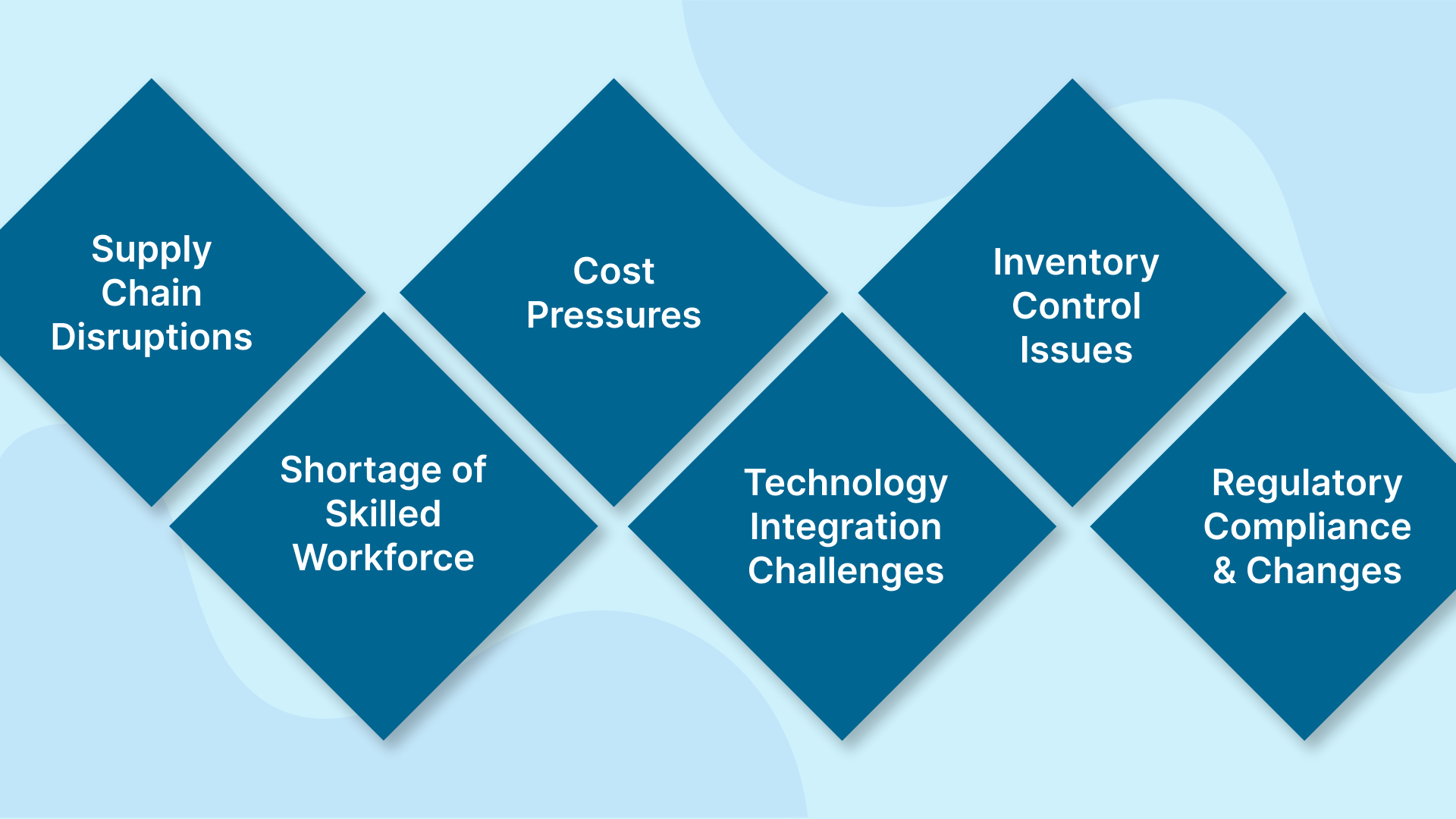

Logistics facilities face numerous challenges, and understanding these obstacles enables businesses to prepare more effectively and optimize their logistics strategy to maintain smooth operations. Here are some of the common hurdles that logistics facilities must manage, along with strategies for overcoming them.

Global events, such as pandemics, natural disasters, and political instability, can disrupt the smooth flow of goods, causing delays and affecting logistics facilities’ ability to fulfill orders on time. Supply chain disruptions have been linked to significant increases in inflation in the Philippines, as bottlenecks and delays raise the cost of goods and services.

As the logistics industry continues to evolve with advanced technology and automation, finding workers who are skilled in operating complex systems is increasingly difficult. This leads to understaffing and operational inefficiencies.

Logistics facilities are constantly under pressure to manage rising operational costs. From increasing energy prices to higher labor and real estate expenses, logistics providers must find ways to maintain efficient service while keeping costs under control. As logistics costs are estimated to consume 27.5% of the Philippines’ GDP, the highest among ASEAN nations, this significantly impacts economic growth, consumer prices, and competitiveness.

Implementing and maintaining cutting-edge technologies, such as Warehouse Management Systems (WMS) or Radio Frequency Identification (RFID) tracking, requires a significant investment in infrastructure and training. In many cases, facilities face resistance to adopting new technologies or struggle to integrate them with existing systems.

Accurate inventory management is crucial to logistics efficiency. Many facilities deal with inaccuracies in stock levels due to human error or outdated systems, which can lead to product shortages or overstocking, resulting in lost sales or increased storage costs.

Logistics facilities must comply with an increasing number of local and international regulations, including safety standards, environmental laws, and customs procedures. Keeping up with frequent regulatory changes can be time-consuming and costly, especially for businesses operating in multiple countries.

These challenges require logistics facilities to be adaptable, continuously improve, and incorporate the right solutions to ensure efficient and cost-effective operations. This leads us to examine how Inspire Solutions helps address these challenges, making logistics more efficient for businesses.

Read: Understanding Logistics Services: Types and Benefits

At Inspire Solutions, we understand the complexities of managing logistics facilities. Our services are tailored to streamline your logistics operations, reduce costs, and improve customer satisfaction. Whether you’re a startup or an established retailer, we make logistics more efficient for your business.

Here’s how our services connect to the core logistics functions:

With our integrated services, you can optimize your logistics operations and drive growth in the digital marketplace.

Efficient logistics operations are at the heart of a successful e-commerce business. By streamlining the flow of goods and ensuring timely deliveries, logistics facilities help businesses reduce costs, improve operational efficiency, and deliver a better customer experience. With the right solutions in place, managing your logistics doesn’t have to be complicated.

At Inspire Solutions, we focus on delivering practical, scalable solutions tailored to your business’s specific needs. We understand the unique challenges you face and offer services that simplify your logistics, whether it’s warehousing, fulfillment, sourcing, or delivery. Our goal is to give you the tools and support you need to run your business smoothly.

Take the next step in simplifying your logistics. Contact us today and discover how we can help you reduce costs, boost efficiency, and deliver outstanding service to your customers. Let’s get started!