Are you facing inventory buildup, delivery delays, and cash flow gaps while demand in the Philippines keeps rising?

Exports and freight flows are increasing rapidly. For example, Philippines port cargo volumes rose by 11% from January to March 2025. However, logistics costs still account for about 27.5% of the country’s GDP, which is the highest among ASEAN nations. Businesses often struggle with outdated systems, hidden bottlenecks, and slow supplier coordination, causing stockouts and unhappy customers.

Efficient supply chains directly affect your ability to meet demand, control expenses, and sustain growth in this fast-moving market. Keeping pace means keeping every part of your chain, from procurement to delivery, aligned and responsive.

The FMCG (Fast-Moving Consumer Goods) system is the one that transports high-volume, low-cost items, such as food, beverages, and toiletries, from producers to consumers. It must operate quickly and efficiently due to the high demand and short shelf lives of these products. In the Philippines alone, revenue in the food market is projected to grow at a 7.85% CAGR in 2030, underscoring the scale and velocity required to keep these supply chains running smoothly.

For better understanding, here’s a quick breakdown of the key stages involved:

Each step in this chain must be tightly coordinated to keep products flowing smoothly and profitably, especially in highly competitive, consumer-driven markets like the Philippines. With the basics covered, it’s time to understand how increased competition is affecting each stage of this chain.

Also read: Understanding the Difference Between Logistics and Supply Chain Management

FMCG brands today compete not only for customer loyalty but also across every layer of their operational supply chain. To meet shifting expectations, you need to outperform rivals in sourcing, inventory control, delivery speed, and overall consistency. The Philippines’ inflation rate eased to 1.4% in April 2025, down from 1.8% in March this year.

Lower inflation slightly boosts consumer spending but also raises pressure on brands to deliver faster and more reliably. In this environment, your supply chain becomes a direct reflection of how well you serve and retain your market.

Here’s how competition is intensifying across key segments of the FMCG supply chain:

These rising pressures tighten margins and introduce new bottlenecks that businesses must address to maintain competitiveness. Next, we’ll explore the real challenges faced daily.

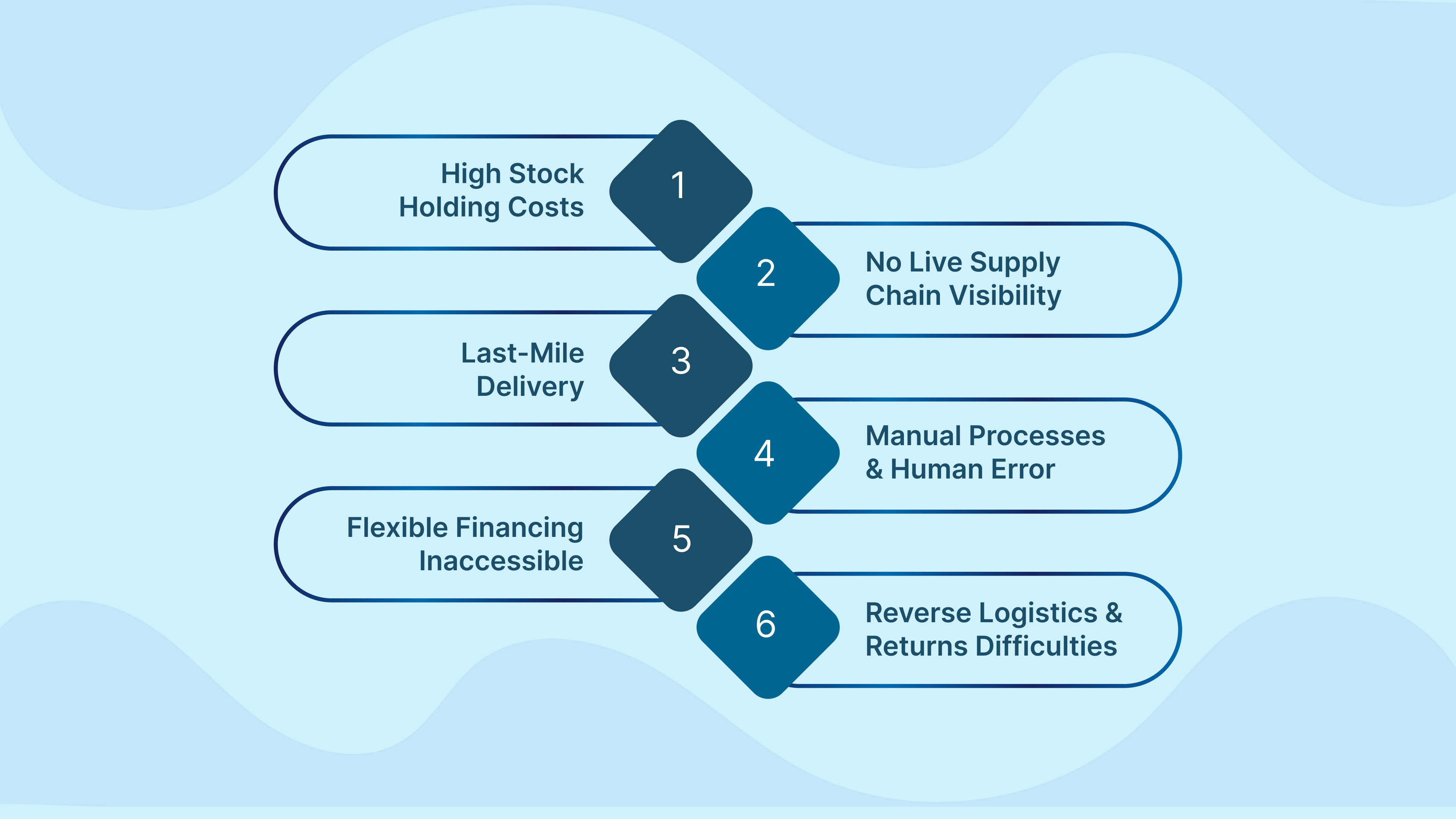

Operating an FMCG supply chain successfully requires more than just speed; it demands precision, visibility, and adaptability at scale. As your operations grow, these specific challenges often become major roadblocks that impact profitability, delivery performance, and overall customer experience.

Storing excess inventory leads to higher warehousing expenses, especially when demand fluctuates unpredictably throughout the year. You either overstock and increase your losses or understock and miss potential revenue from unfulfilled orders. Balancing stock levels without accurate forecasting makes growth unsustainable and forces you to absorb unnecessary operational costs.

In the absence of real-time visibility, organizations often face uncertainty regarding the location of inventory and the estimated completion times for deliveries. This slows down your ability to respond, often causing service delays and negative customer experiences you could have prevented. Real-time data enables quick decisions that reduce uncertainty and keep operations aligned.

Delivery delays during the final leg impact customer satisfaction, especially in traffic-heavy areas with tight delivery windows. Without optimized routes or responsive carriers, you lose both time and trust in every failed handoff. Customers expect speed and consistency, which your competitors may already be delivering better than you.

When operations rely on manual work, you experience data entry mistakes, slower fulfillment, and inconsistent customer service outcomes. These inefficiencies scale with your business, making it harder to maintain accuracy and control during high-demand periods. Automation eliminates those delays and reduces dependence on overworked staff resources.

Without accessible financing, it’s difficult to invest in inventory, technology, or manpower when sudden growth opportunities appear. Traditional loans involve lengthy approval times that force you to delay expansion, restocking, or system upgrades. Flexible capital ensures you stay agile while your competitors may remain constrained.

Handling product returns manually creates confusion, inventory mismatches, and delayed refunds that frustrate your customers and staff. Reverse logistics requires coordination and structure that many small e-commerce businesses still lack in their daily operations. A seamless return process is essential to preserving customer trust and operational flow.

While these hurdles are real, there are proven ways to work around them. Here’s how you can take control instead of playing catch-up.

Also Read: Supply Chain Examples and Effective Strategies Explained

Effective strategies are essential in the FMCG space to ensure streamlined operations, stay competitive, and adapt quickly to market changes. Below are proven approaches you can implement to optimize each part of your supply chain without adding complexity.

Real-time visibility allows you to track inventory, monitor movement, and respond to disruptions before they impact customers. This helps you reduce errors, improve forecasting, and gain better control over every node in your logistics flow.

Automation removes guesswork and human error, enabling you to manage higher-order volumes without sacrificing fulfillment speed. You gain better efficiency, fewer mistakes, and improved accuracy across your entire backend operation.

Last-mile delivery directly influences customer satisfaction, making it a top priority for any FMCG brand that wants to grow. Strengthening your delivery options ensures speed, consistency, and higher rates of successful, on-time drop-offs.

Cash flow limitations can delay payments and reduce available working capital, restricting your ability to upgrade systems, invest in growth, or capitalize on bulk purchasing.

A simplified sourcing model ensures that you maintain product quality, reduce lead times, and minimize customs-related delays. By digitizing the process, you gain more control over supplier communications, product selection, and shipment coordination.

These strategies can get you far, but execution is everything. That’s where Inspire Solutions Asia steps in to make it work. Inspire Solutions Asia empowers your FMCG supply chain strategies with integrated solutions built for speed, scale, and simplicity.

FMCG brands operating in fast-moving markets like the Philippines need simple, scalable infrastructure to compete and grow sustainably. After exploring general strategies to optimize your FMCG supply chain, here’s how Inspire Solutions Asia’s integrated services can support these efforts.

Here’s how their core solutions support your FMCG supply chain optimization efforts:

Today’s FMCG supply chain requires not only speed but also careful accuracy, flexibility, and adaptable systems that keep up with changing market needs. Whether you’re launching a new venture or scaling your operations, optimization is no longer optional; it’s business-critical.

When you streamline warehousing, automate fulfillment, simplify sourcing, and secure flexible financing, your business gains operational clarity and a competitive edge. Inspire Solutions Asia gives you the infrastructure to move faster, cut costs, and serve your customers with unmatched reliability. As digital commerce evolves in the Philippines and Southeast Asia, a responsive supply chain positions you to scale confidently. With real-time visibility, reliable delivery, and scalable tools, you’ll spend less time managing chaos and more time growing. Whether you’re an emerging entrepreneur or a mature online retailer, your success starts with integrated systems that work in sync.

Ready to optimize your FMCG supply chain? Schedule a free consultation with Inspire Solutions Asia today.

1. What makes FMCG supply chains different from other industries?

FMCG supply chains move high-volume, fast-turnover goods, requiring speed, precision, and minimal delays at every stage.

2. Why is last-mile delivery so important in FMCG logistics?

It directly affects customer satisfaction, brand trust, and repeat purchases, especially in urban markets with tight delivery windows.

3. How can automation improve FMCG supply chain performance?

Automation reduces manual errors, accelerates fulfillment, and improves accuracy in inventory tracking and order processing.

4. What role does real-time visibility play in FMCG operations?

It helps businesses quickly identify issues, manage inventory levels, and make data-backed decisions during disruptions or demand shifts.

5. How does flexible financing support supply chain growth?

It enables faster inventory restocking, system upgrades, and scaling—without waiting on lengthy bank approvals or tying up capital.