Port congestion occurs when an excessive number of ships attempt to use a port simultaneously, causing delays in unloading and moving goods. At Manila Port, the average wait time for dry bulk vessels has increased from 6.5 to 10 days as of April 28, 2025, with overall ship wait times ranging from 7 to 10 days due to limited infrastructure and high cargo volumes. This congestion affects businesses that rely on timely deliveries, disrupting inventory cycles and causing imbalances, stockouts, and higher shipping costs.

Port congestion occurs when cargo ships experience delays at seaports due to slow unloading, limited infrastructure, or cargo backlogs. This results in longer wait times, higher costs, and supply chain disruptions.

If you rely on imports or time-sensitive deliveries, these delays can impact your ability to restock inventory, fulfill orders, and meet customer expectations. For e-commerce operations, especially in fast-moving markets like the Philippines, even minor port delays can disrupt fulfillment and hurt customer satisfaction.

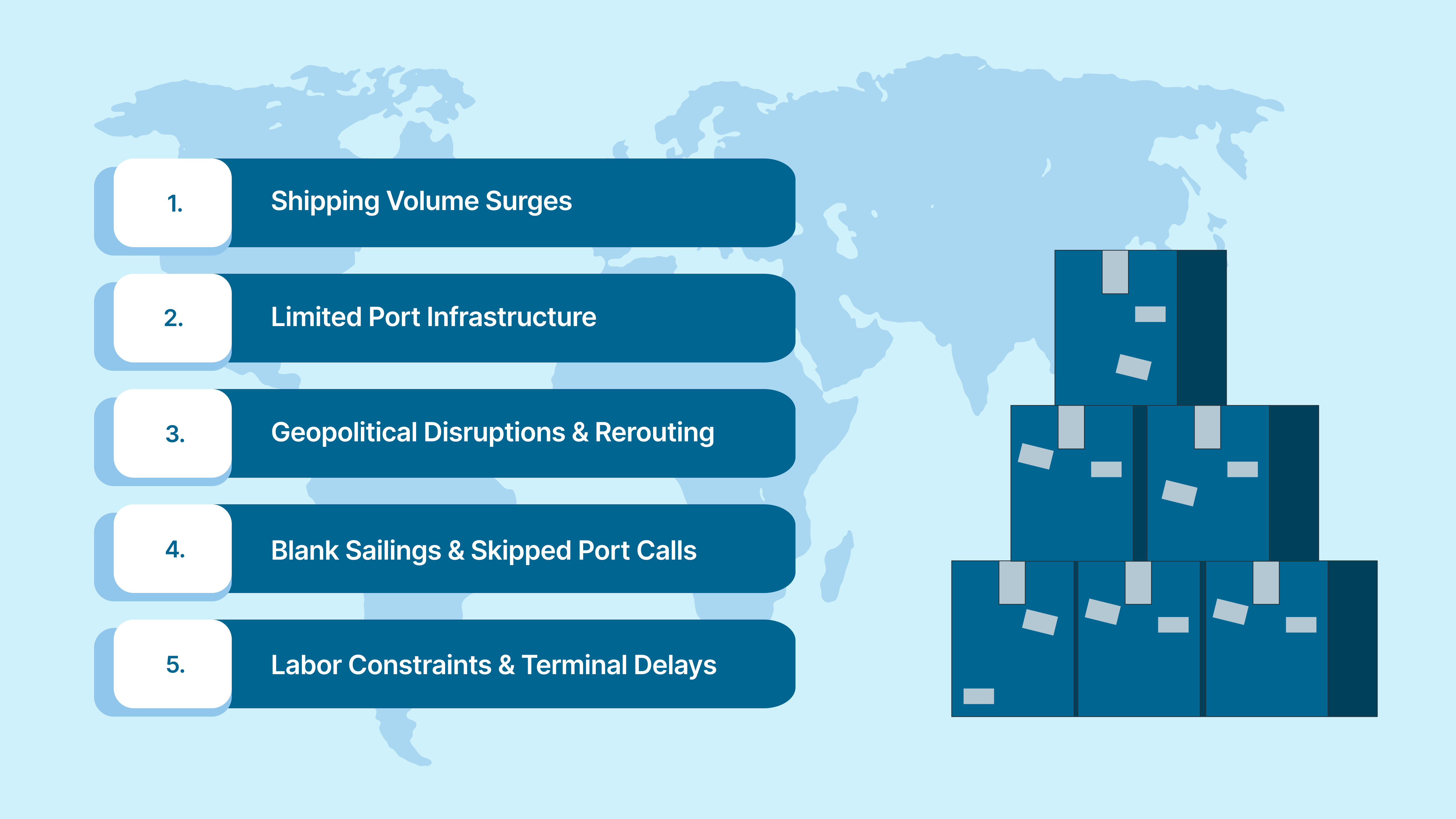

The factors behind port congestion are multifaceted. To understand the root of the issue, we’ll now look at the causes driving these delays.

In 2025, port congestion is caused by issues such as outdated facilities, uneven shipment volumes, and limited space, particularly at busy ports like Manila and Los Angeles. These issues disrupt cargo movement and create ripple effects that directly impact your delivery timelines, inventory planning, and customer experience.

Below are the core causes and why they matter to your business:

Understanding these causes sets the stage for realizing just how deeply the effects of port congestion impact business operations. Let’s now see how these delays directly affect your shipping and logistics.

Also read: Essential Shipping Documents for Import and Export

For any business relying on imports, exports, or regional distribution, port congestion disrupts the flow of goods at the most critical handover points. Here’s how it directly impacts your shipping and logistics:

In the next section, we’ll examine how these shipping delays affect your business performance and profitability.

Also Read: How to Reduce Logistics Costs: Effective Strategies

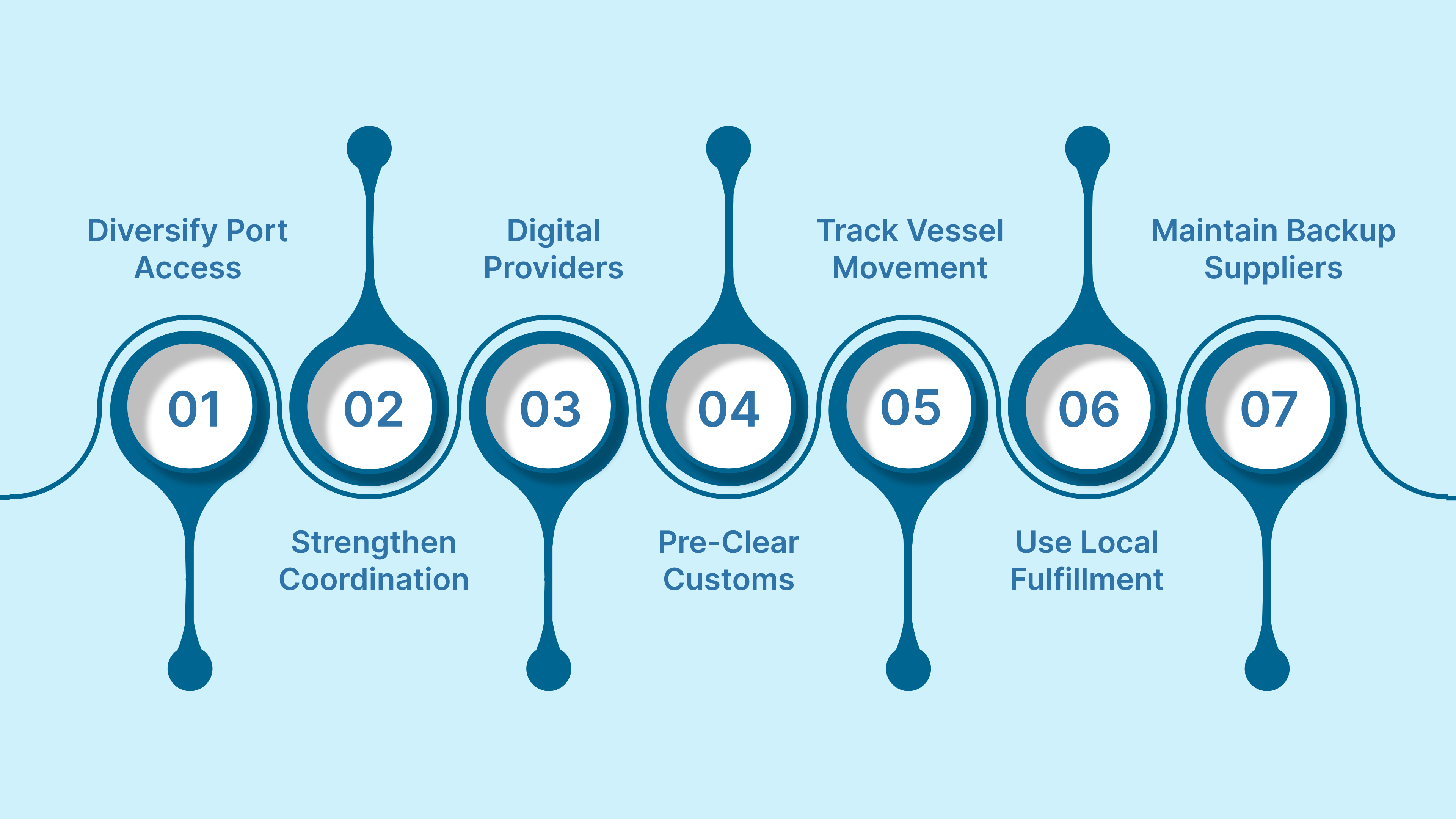

Reducing the effects of port congestion isn’t just about reacting quickly; it’s also about anticipating and mitigating potential issues. It’s about building resilient systems that give you control, even when external conditions shift.

Below are proven strategies to help you protect delivery timelines, reduce costs, and keep your supply chain moving, especially if you’re managing e-commerce or cross-border trade in the Philippines or Southeast Asia.

Relying on just one port can cause problems if there’s a delay, so using different ports, such as Subic Bay, Batangas, or Davao, can help keep your shipments moving smoothly even if one port has a backup.

Even if your goods clear the port on time, problems with trucks or deliveries can still cause delays. You need to know how your products will get from the port to your store or warehouse. Work with delivery partners who can manage the entire journey from the port to your door. This helps ensure you don’t lose time and meet deadlines, even when there are disruptions like adverse weather conditions.

Outdated logistics systems relying on manual tracking and paperwork can cause errors and delays, but solutions like Inspire Solutions Asia offer streamlined warehousing, real-time inventory management, and automated order fulfillment tailored for e-commerce businesses in the Philippines.

Waiting for customs to clear your goods can result in a significant delay. If you send your documents ahead of time, you can expedite the customs clearance process for your goods. Online platforms can simplify the process of submitting papers and reduce the likelihood of errors. By taking care of customs before the shipment arrives, you’ll speed up the process and avoid delays or fines.

To prevent delays, monitor ships and port conditions carefully. Watch for factors like ship arrival times and whether the port is overcrowded. Digital tracking platforms provide forecasts on vessel arrivals and weather conditions, enabling proactive route adjustments and minimizing delays.

If you store your products closer to your customers, you’ll be less affected by international shipping delays. Local warehouses help you ship faster, even if your goods are still at the port. You can also utilize flexible fulfillment centers that adjust to sudden changes in demand, which is particularly helpful in places like the Philippines, where delivery speed is a key consideration for customers.

If you rely on just one supplier or route, you might face serious problems when delays happen. Ensure you have alternative suppliers to work with and maintain an extra stock of essential items. This way, even if there’s a delay, you can keep your business running without problems.

With these practical solutions, it’s possible to reduce the impact of port congestion on your business. But how do these disruptions truly affect your operations? Let’s take a closer look at how port delays impact your bottom line.

Also Read: Understanding Customs Clearance: Meaning and Process Guide

Port congestion delays shipments and triggers a chain reaction impacting operations, costs, and customer experience in the following ways:

The ripple effect of port congestion extends far beyond logistics. It encompasses customer experience, cost control, and financial stability. So, how can your business manage these challenges? Let’s take a closer look at how Inspire Solutions Asia can help you navigate these issues with better control.

Port congestion persists and will continue to affect shipping, fulfillment, and costs, putting ongoing pressure on e-commerce businesses like yours. However, with the right strategies in place, you can minimize disruptions, safeguard customer trust, and maintain a competitive edge.

Diversifying shipping routes, utilizing tech-driven logistics partners, and securing inventory buffers are just some of the ways Inspire Solutions Asia stands out. Their integrated ecosystem, encompassing warehousing, fulfillment, importation, financing, same-day & next-day delivery, and last-mile delivery, is designed to help businesses like yours mitigate volatility, reduce delays, and operate with agility. If you’re looking to stay resilient amid port delays, now’s the time to explore Inspire’s flexible financing solutions to ease cash flow and secure essential inventory, and inquire about Same Day & Next-Day Delivery services to ensure your customers receive their orders without disruption.

Discover how Inspire Solutions Asia can help you turn logistics challenges into competitive advantages. Schedule your consultation Now!